SSP fabricates EMI gaskets in low minimum order quantities and with fast turnaround times.

We’re a Made in USA manufacturer that makes our own materials and tooling with ISO 9001:2015 quality.

Choose standard EMI gaskets in M83528 slash sizes or custom products that are made-to-order.

SSP’s MIL-DTL-83528 Type A, B, C, D, and K silicones and fluorosilicones are QPL certified, and our nickel-graphite EMI gaskets are cost-effective.

Fabrication processes include flash cutting, die cutting, compression molding, and PSA lamination.

We invite you to compare SSP’s EMI gaskets to Parker Chomerics CHO-SEAL, Nolato Jabar, and Schlegel EMI.

EMI gaskets from SSP don’t just provide shielding against electromagnetic interference (EMI). They also deliver environmental sealing and thermal insulation. SSP’s EMI gaskets are used in both military and civilian applications. They’re made of silicone elastomers that are filled with metal or metal-coated particles to provide electrical conductivity. Silicone is normally an electrical insulator, but the addition of metal particles imparts the necessary electrical conductivity.

EMI gaskets seal the gap between two mating surfaces, such as a housing and a lid. They’re used in electronic, avionics, and electrical enclosures, but also with waveguides and electrical connectors. Like other types of environmental seals, EMI gaskets from SSP keep out the external environment or seal-in to prevent leakage. What makes EMI gaskets different is that they also seal against conducted or radiated EMI that can interfere with circuits. When this electromagnetic “noise” reaches the EMI gasket, the signals are negated and the resulting electrical current is sent to ground.

EMI gasket materials from SSP use silicone or fluorosilicone as the base elastomer. They are filled with metal, metal-coated, or bimetallic materials that impart electrical conductivity.

SSP fabricates your EMI gasket from shielding silicones and fluorosilicones in the following types.

Ask SSP for standard or custom EMI gaskets, including M83528 part numbers. We offer low minimum order quantities (MOQs) and quick turn-around times for cut or molded parts. Compare our materials to Parker Chomerics CHO-SEAL, Nolato Jabar, and W.L. Gore products.

SSP fabricates EMI gaskets from EMI silicone sheets and EMI silicone rolls in standard and custom sizes. We also fabricate gaskets from EMI extrusions and ready-to-mold compounds. SSP can flash cut, die cut, or compression mold EMI gaskets from the shielding silicones that we make. SSP can also apply pressure-sensitive adhesive (PSA) backings for ease-of-installation. Gaskets that are cut from EMI extrusions can be cold bonded or hot spliced.

Managing electromagnetic interference (EMI) and radio-frequency interference (RFI) is critical for performance and regulatory compliance. To minimize enclosure integrity, engineers need to minimize the leakage of unwanted emissions or the ingress of internal signals. Die cut EMI gaskets from SSP can help.

This article is written for engineers who design or specify EMI shielding gaskets, with a focus on die-cut conductive elastomers, material choices, design considerations, and best practices. Specialty Silicone Products, Inc. (SSP) makes a full line of EMI/RFI shielding silicones, and we have our own toolroom we can machine dies.

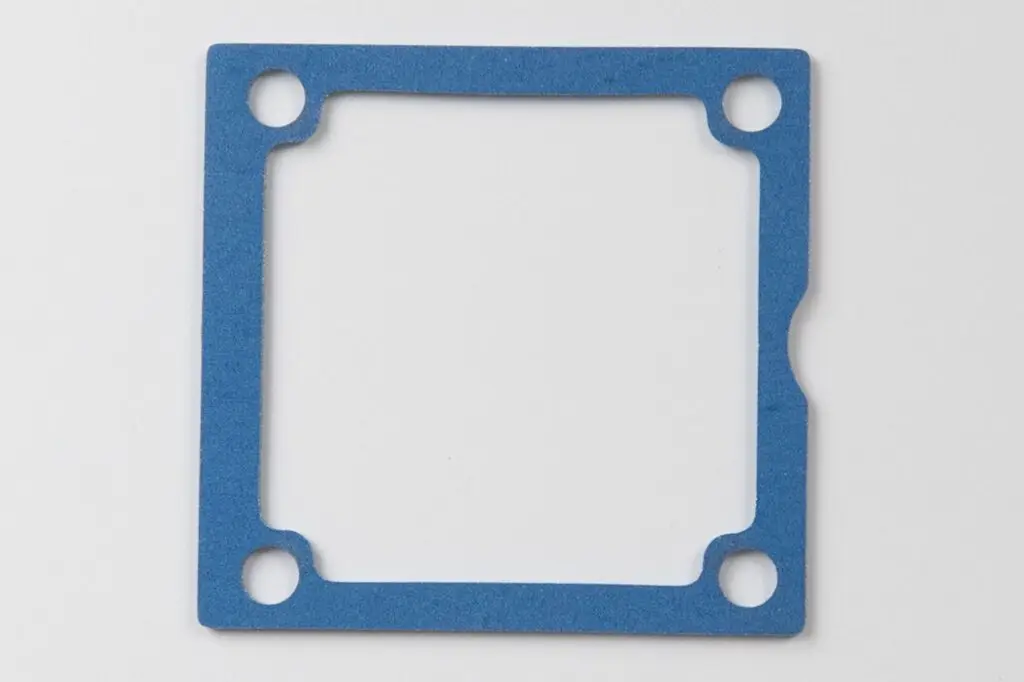

A die-cut EMI gasket is a part that’s fabricated from a sheet or roll of an electrically conductive elastomeric material. The gasket is cut with a steel-rule or other type of die to a specified geometry that matches the enclosure flange or mating surfaces.

When compressed, the EMI gasket forms an environmental seal against dust, humidity, moisture. It also forms an electrical path so that the cut gasket becomes part of the shielding interface between the enclosure halves or between a chassis and cover.

When selecting die cut emi gasket materials, consider what SSP offers and how we offer a choice of electrically conductive elastomers.

Key features of SSP’s EMI shielding silicones include:

When specifying and designing products, consider electrical shielding performance, mechanical sealing performance, environmental durability and manufacturability. Here are some general guidelines.

A die cut EMI gasket must provide a reliable electrical contact between the enclosure halves or mating surfaces, closing the electromagnetic path and thus lowering transfer impedance or insertion loss. Importantly, gaskets must be properly deflected to perform, and each type of gasket and cross section has a unique deflection curve.

Because EMI silicone gaskets contain electrically conductive fillers (e.g., nickel, silver-plated aluminum), engineers should verify vendor test data and understand the frequency range. Many of SSP’s EMI shielding silicones have been third-party tested, and we share these test reports right on our website.

Simulating an enclosure’s environment can help prevent seal failure. For example, will the EMI seal undergo temperature cycling, vibration, chemical exposure, salt spray, or vacuum conditions? SSP categorizes materials accordingly and offers materials that are corrosion resistant, fuel/solvent resistant, or have low silicone outgassing.

Mechanical factors to consider include compression set, tear/elongation performance, and durability under repeated assembly/disassembly hinge cycles.

A die cut EMI gasket needs to provide both electrical and environmental sealing. Remember to optimize the geometry because material selection alone doesn’t guarantee sealing performance. Also, consider whether the enclosure uses bolts, latches or hinges, and design the gasket geometry accordingly (e.g., thickness, cross-section, cut features, adhesives).

Die cut EMI gaskets offer advantages in rapid production and lower tooling costs compared to custom molded parts. However, early design for manufacturability (DFM) is needed. The placement of bolt holes, tolerances, adhesive backing, sheet size, scrap waste and die-cut tolerances must all be addressed.

Some of the more frequent oversights in product specifications include hole placements too close to the edge, ignoring adhesive ageing or incorrect PSA selection, and tolerances that are inappropriate for die cutting.

For engineers specifying die-cut EMI gaskets, follow these best practices:

Die-cut EMI gaskets made from conductive silicone elastomers are a versatile and effective solution for engineers seeking to provide both environmental sealing and electromagnetic shielding in electronic enclosures. SSP manufactures a wide range of EMI shielding silicones and can fabricate the materials we make into die cut EMI gaskets.

Contact SSP to request a quote or for more information.

EMI gasket standards include requirements for EMI shielding and environmental sealing. Some standards, such as NEMA and IP ratings, apply only to environmental sealing but may still affect EMI gaskets made of electrically conductive silicones. In addition to NEMA, the following organizations maintain standards that EMI gasket designers may need to meet.

For some military applications, EMI gaskets must use materials that meet MIL-DTL-83528 requirements. MIL-DTL-83528 is a detail specification from the DoD that establishes general requirements for electrically-conductive elastomeric shielding gaskets. MIL-DTL-83528 contains lettered sections, each of which contains requirements for the base elastomer, durometer, fill material, plane wave shielding effectiveness, and continuous use temperature. Because MIL-DTL-83528 only applies to fill materials that are pure silver or silver-coated, it does not encompass nickel-graphite filled silicones or wire-oriented silicones that contain Monel or aluminum mesh.

UL maintains two flammability standards that may apply to EMI gaskets: UL 94 V0 and UL 50-E. Neither standard is silicone-specific, and both apply to plastics. UL 94 V-0 is part of a larger standard, UL 94, that classifies materials according to how they burn in various orientations and part thicknesses. UL 50E is an IP standard against dust and water that applies to enclosures for electrical equipment that will be installed and used in non-hazardous locations.

For EMI gaskets that require resistance to galvanic corrosion, such as those used in marine environments, ASTM B117 may apply. Galvanic corrosion occurs when two dissimilar metals are immersed in a conductive solution, such as salt water, and are electrically connected. There are also electrically conductive silicones for EMI gaskets that need to meet ASTM E595 for outgassing, a problem in high vacuum environments, such as outer space, where released gases can condense upon and cloud optics.

This video shows how SSP’s in-house machine shop makes the tooling we use for EMI gaskets.

MIL-DTL-83528 QPL Certified EMI gaskets meet the requirements of MIL-DTL-83528 and are part of the Qualified Products List (QPL) for this specification. MIL-DTL-83528 (MIL-G-83528) is a U.S. military specification that defines conductive elastomer types and shielding effectiveness levels. Materials on the M83528 QPL meet all MIL-DTL-83528 requirements and have been tested by the Defense Logistics Agency (DLA), which is part of the U.S. Department of Defense (DoD).

M83528 part numbers are fabricated from materials that meet the requirements of the MIL-DTL-83528 specification. They are divided into numeric types that are preceded by a slash (/). That’s why these part number designations are also called slash sizes.

Use the table below to find M83528 part numbers.

Specification Sheet | Short Description | Long Description |

M83528/001 | Gasketing Material, Conductive, Shielding Gasket, Electronic, Elastomer, EMI/RFI, Circular Strip, .040 Through .250 Diameter. | |

M83528/002 | Gasketing Material, Conductive, Shielding Gasket, Electrical, O-Ring, Standard. | |

M83528/003 | Gasketing Material, Conductive, Shielding Gasket, Electronic, Elastomer, EMI/RFI, Solid “D” Shaped Strip. | |

M83528/004 | Gasketing Material, Conductive, Shielding Gasket, Electronic, EMI/RFI, Connector Flange Mount. | |

M83528/005 | Gasketing Material, Conductive, Shielding Gasket, Electronic, Elastomer, EMI/RFI, O-Ring, Non-Standard. | |

M83528/006 | Gasketing Material, Conductive, Shielding Gasket, Electronic, Elastomer, EMI/RFI, Rectangular, D-Cross Section. | |

M83528/007 | Gasketing Material, Conductive, Shielding Gasket, Electronic, Elastomer, EMI/RFI, Hollow D-Strip. | |

M83528/008 | Gasketing Material, Conductive, Shielding Gasket, Electronic, Elastomer, EMI/RFI, Hollow P-Strip. | |

M83528/009 | Gasketing Material, Conductive, Shielding Gasket, Electronic, Elastomer, EMI/RFI, Solid Rectangular Strips. | |

M83528/010 | Gasketing Material, Conductive, Elastomer, Electrical, EMI/RFI, Channel Strip. | |

M83528/011 | Gasketing Material, Conductive, Shielding Gasket, Electronic, Elastomer, EMI/RFI, Hollow O-Strip. | |

M83528/012 | Gasketing Material, Conductive, Shielding Gasket, Electronic, Elastomer, Electrical, EMI/RFI, Flat Circular Washer. | |

M83528/013 | Gasketing Material, Conductive, Shielding Gasket, Electronic, Elastomer, Electrical, EMI/RFI, Waveguide. | |

M83528/014 | Time Totalizing Meter | Gasketing Material, Conductive, Shielding Gasket, Electronic, Elastomer, EMI/RFI, for Use in Time Totalizing Meters Covered by MIL-M-7793. |

MIL-DTL-83528 is divided into lettered sections. SSP makes MIL-DTL-83528 QPL certified EMI gasket materials that meet the requirements of A, B, C, D, and K, as shown in the table below.

Type | Base Elastomer | Filler | Typical Applications | Key Strengths |

Silicone | Silver-Copper | Aerospace enclosures | High shielding effectiveness | |

Silicone | Silver-Copper | Military electronics | Good balance of shielding and other properties | |

Fluorosilicone | Silver-Copper | Jet fuel environments | High shielding effectiveness | |

Fluorosilicone | Silver-Aluminum | Harsh aerospace environments | Good balance of shielding and other properties | |

Silicone | Silver-Copper | Commercial/industrial | High shielding effectiveness |

Click the images or links below to learn more about SSP’s MIL-DTL-83528 Type A, B, C, D, and K materials.

Corrosion resistant EMI gaskets resist galvanic corrosion, which occurs two dissimilar metals are in contact with each other in the presence of an electrolyte (like water or salt solution) and an electrical current flows between them, causing one metal to corrode preferentially.

SSP’s corrosion resistant EMI gasket materials are shown below. These nickel-aluminum-filled silicones are a cost-effective alternative to silver-filled EMI shielding gaskets. SSP2529 is an offset to CHO-SEAL 6502 and SSP2551 is an offset to CHO-SEAL 6503.

Corrosion resistant EMI gaskets are used in environments where enclosures require EMI shielding and are exposed to harsh environments with moisture, salt, chemicals, or temperature extremes. Other gasket materials can rapidly degrade, but corrosion resistant EMI gaskets maintain sealing and shielding over time. They are used in these and other applications.

Nickel-aluminum-filled silicones exhibit the lowest amount of flange pitting from galvanic corrosion, an electrochemical process that occurs when two different metals are in contact in a saltwater environment. These shielding silicones also exhibit excellent galvanic stability with aluminum flanges.

Soft EMI gaskets are made of shielding silicones with durometers as low as 30 Shore A. They provide reliable sealing under low closure force.

Like other types of elastomeric gaskets, a soft EMI shielding gasket is compressed by a percentage of its size. This compression forms a seal that physically fills the gap between two surfaces. When the compressive stresses are removed, the EMI gasket is supposed to return to its original thickness. If it does not, this irrevocable deformation (compression set) can leave a gap and cause seal failure.

Note: Harder materials with higher durometers are more difficult to compress, but electrically conductive silicones are not excessively hard because of the addition of particles. In fact, EMI silicones are available in a range of hardnesses, including lower durometers for gaskets where there is less closure force.

Soft EMI gasket materials from SSP include SSP502-30, a nickel-graphite shielding silicone that is comparable to CHO-SEAL S6305, 6330, 6370, 6371, 6372, and 6308. Also filled with nickel-graphite is SSP502-40 silicone, an offset to CHO-SEAL S6305, 6330, 6370, 6371, 6372, and 6308.

Other soft EMI gasket materials are available as well. SSP502-40-V0 is a soft, nickel-graphite silicone that is an offset to GORE GS2100 and provides UL 94V0 flame resistance. SSP550-45 is a soft, silver-aluminum fluorosilicone with ASTM E595 low outgassing that is comparable to CHO-SEAL 1287 and 1298.

Fuel resistant EMI gaskets are made of fluorosilicones. They are used in military and civilian applications that require resistance to harsh chemicals, including fuels and solvents.

Fuel and solvent resistant EMI gaskets can be fabricated from a QPL certified MIL-DTL-83528, Type D elastomer and nickel-graphite materials in 50, 60, and 80 durometer (Shore A).

SSP also offers two two silver-aluminum fluorosilicones, including a passivated product. Passivation increases the corrosion resistance of the electrically conductive metal particles.

Fluorosilicones combine the high and low-temperature resistance of silicones with the fuel and oil resistance of fluorocarbons. Compounds that are filled with metal or metal-coated particles also provide electrical conductivity and EMI shielding.

Low outgassing EMI gaskets are made of shielding elastomers that meet ASTM E595 requirements for low levels of silicone outgassing, or offgassing, that can occur in vacuum environments like outer space. ASTM E595 is a standard test method that determines total mass loss (TML) and collected volatile condensable materials (CVCM).

Low outgassing EMI gaskets are used in satellite communications, typically as gaskets for optics, sensors, and electronics that could cloud from silicone outgassing in the vacuum environment of space.

SSP’s low outgassing EMI materials include a QPL certified MIL-DTL-83528, Type B offset to CHO-SEAL 1285 and an offset to CHO-SEAL 6502. Low-outgassing flame retardant offsets to GORE GS2100 and GORE GS5200 are also available. In addition, SSP makes shielding gaskets from an EMI silicone for extreme low temperature environments and a silver-aluminum fluorosilicone.

The most electrically conductive EMI gaskets have silver-coated particles. Silver is the best electrical conductor because its valence electron is loosely bound and moves easily with very little resistance through the metal’s crystal structure.

SSP’s most electrically conductive EMI gaskets can be made two MIL-DTL-83528 QPL certified EMI silicones that are filled with silver-copper.

There are also three other SSP materials for the most electrically conductive EMI gaskets.

The EMI shielding that’s used in automotive, aerospace, and medical electronics must meet multiple design requirements. For example, an EMI gasket that’s used with aircraft may need to resist the splash of jet fuel. Shielding that’s used with EV charging stations may require compliance with UL 94 standards for flammability.

Flame-retardant EMI gaskets materials are made of shielding silicones with a UL 94 V0 flame rating. They contain nickel-graphite particles and meet ASTM E595 requirements for low levels of outgassing. Applications include wireless infrastructure equipment, telecommunications equipment, portable electronic devices, microwave equipment, high frequency cable connectors, military programs and spaceflight.

Use SSP’s flame rated EMI shielding materials instead of GS2100 or GS5200 from W.L. GORE, which discontinued these popular GORE-SHIELD® materials in 2020.

Reinforced EMI gaskets contain nickel-graphite particles and are reinforced with an inner layer of conductive fabric. They are fabricated from sheet or rolls materials that come in four different inch-based thicknesses: .020, .024, .032, .040, and .062.

Reinforced EMI gaskets are used in applications where there is a risk of tearing. The conductive fabric layer enhances electrical conductivity and provides mechanical strength and flexibility. They are used in these and other applications.

SSP offers two composite materials, both of which have physical properties that are superior to non-reinforced elastomers.

The most cost effective EMI gaskets are made from a nickel-graphite EMI silicone. Theys are suitable for applications where cost is a key consideration. Examples include low-cost electronics such as some mobile devices.

SSP’s most-cost effective EMI shielding silicone, SSP502-65, supports thinner, smaller, and lighter weight designs. It’s also an offset to CHO-SEAL 6305. This 65-durometer nickel-graphite EMI elastomer offers performance levels that are comparable to shielding silicones with silver-coated particles. Independent test results for salt spray according to ASTM B117 are also available.

Non-silicone EMI gaskets are made from a 75-durometer nickel-coated EPDM shielding elastomer. They are used in applications that require silicone-free products with low outgassing. Examples include clean or optical environments and production facilities that do not allow silicones to minimize the risk of surface defects in coatings, paints, or adhesives.

SSP2514-75 EMI gasket material provides excellent ozone and UV resistance along with good compression set and solvent resistance. As with all SSP’s EMI shielding elastomers, customized versions are available in different durometers.

SSP supplies mold-able EMI silicones. For frame gaskets, molding minimizes material waste, maximizes material yields, and eliminates the need to bond cut lengths. Fabrication processes like die cutting are efficient, but the cut-out section of a frame gasket can represent significant material waste.

By their very nature, EVs place a large amount of electrical and electronic content into confined spaces. The radiated and conducted emissions from these systems can disrupt circuits and result in conditions that range from minor inconveniences to dangerous losses of vehicle function. There are sources of EMI outside of the vehicle as well.

What’s the difference between EMI silicone gaskets and EMI fluorosilicone gaskets? Even more importantly, which material should you select?

EMI silicone gaskets provide excellent flexibility and reliable performance across a wide temperature range. They provide good resistance to moisture, ozone, and UV rays. However, EMI silicone gaskets have poor resistance to non-polar solvents, fuels, and oils.

EMI fluorosilicone gaskets are recommended for applications that require resistance to chemicals, fuels, and oils, such as in aerospace or automotive systems. EMI fluorosilicone gaskets are more expensive, but they provide superior resistance to petroleum products, solvents, and harsh chemicals.

If you wondering which type of EMI elastomer to select, consider chemical exposure, cost vs. performance, and temperature range. Both materials offer wide temperature stability, but fluorosilicone excels in environments with petroleum products at varying temperatures.

Effective shielding is not something to “add at the end.” Instead, integrate shielding early in the design process.

Here are some key design considerations.

Different materials and geometries perform better at different frequencies.

Conductive elastomers require specific compression ranges (typically 10–30%) to maintain conductivity and sealing.

Repeated opening/closing of enclosures requires materials that resist compression set and mechanical fatigue.

Below is a list of frequently asked questions (with answers_ about EMI gaskets.

Answer: MIL-DTL-83528 is a U.S. military specification that defines performance requirements for conductive elastomer EMI gaskets. It specifies shielding effectiveness, filler types, environmental resistance, and compliance testing. SSP’s QPL-listed EMI gaskets meet these standards for aerospace, defense, and other high-reliability applications.

Answer: EMI gaskets are typically made from conductive silicone or fluorosilicone elastomers filled with conductive particles such as silver-aluminum, silver-copper, or nickel-graphite. The choice of material depends on environmental exposure, required shielding level, and cost considerations.

Answer: SSP’s MIL-DTL-83528 EMI gaskets deliver shielding effectiveness up to 110 dB at 10 GHz, depending on the filler and base elastomer. Performance varies by gasket type and installation method.

Answer: EMI gaskets are essential in aerospace, defense, medical devices, telecommunications, and industrial equipment. They are used anywhere EMI shielding and environmental sealing are required.

Answer: Yes. Conductive elastomer EMI gaskets provide both EMI/RFI shielding and environmental sealing against dust, moisture, and contaminants. Fluorosilicone grades also resist fuels, solvents, and aggressive chemicals.

SSP makes shielding gaskets that provide shielding against electromagnetic interference (EMI) or radio frequency interference (RFI) with environmental sealing. We make our shielding gaskets from the EMI silicones and fluorosilicones that we produce at our Ballston Spa, New York (USA) manufacturing facility.

Answer: Shielding gaskets are used to block EMI and RFI in electronic devices. They fill gaps or seams in enclosures, preventing unwanted signal leakage and maintaining compliance with industry regulations.

Answer: Shielding gaskets are made from conductive materials such as metal-filled elastomers, woven metal mesh, or conductive foams. They are commonly used in enclosures for electronic equipment, telecommunications devices, medical instruments, and military applications to enhance signal integrity and protect sensitive components from interference.

Answer: These EMC gaskets come in various shapes and sizes, including strip, O-ring, and custom die-cut designs, to fit different enclosure requirements. Some products also provide environmental sealing against dust, moisture, and temperature fluctuations, improving overall device durability.

Answer: The key advantages of these gaskets include easy installation, flexibility, and the ability to conform to irregular surfaces. They help manufacturers meet electromagnetic compatibility (EMC) standards, ensuring that electronic systems function reliably without interference from external or internal sources. Overall, these gaskets play a crucial role in maintaining the performance and reliability of electronic systems by preventing EMI/RFI disruptions in critical applications.

Answer: EMI gaskets are also called shielding gaskets because they provide shielding against electromagnetic interference (EMI). The “gasket” part of the phrase “EMI gasket” refers to how these fabricated products provide environmental sealing and insulation, typically against water and temperatures but sometimes against chemicals, abrasion, or other factors.