MIL-DTL-83528 Type A

CHO-SEAL 1215 alternative. SSP2569-65 is a 65-durometer, silver-copper EMI shielding silicone. MIL-DTL-83528 Type A. QPL Listed.

SSP makes connector gaskets for electrical and electronic connectors that reduce or eliminate the transmission of electromagnetic interference (EMI) between connected devices, or through the connector itself.

We fabricate our products from the EMI elastomers that we make. Many of our materials are MIL-DTL-83528 QPL certified (MIL-G-83528) and can be used for M83528/004 flange mounted gaskets.

Choose SSP’s products and materials instead of Parker Chomerics CHO-SEAL. We offer low minimum order quantities, quick turnarounds, and you can buy from us directly.

EMI connector gaskets provide environmental sealing and shielding against electromagnetic interference (EMI) in electrical and electronic connectors. They are cut or molded from electrically-conductive elastomers and designed to fill small gaps between uneven connector surfaces. EMI silicones for connector gaskets are soft enough to support compression and can provide proven levels of EMI shielding while resisting water, moisture, many chemicals, and a wide range of temperatures.

Specialty Silicone Products makes EMI connector gaskets and supplies gasket fabricators with a choice of connector gasket materials, including MIL-DTL-83528 silicones and fluorosilicones. For higher volumes of gaskets, many fabricators use die-cutting to convert SSP’s compression molded sheets or continuous rolls. For prototyping and lower volumes, flash cutting is a good choice because there’s no tooling to pay for or wait for. SSP can flash-cut EMI connector gaskets and we can custom mold EMI gaskets if you need them.

Note: SSP also makes EMI waveguide gaskets and other fabricated producs.

SSP makes connector gaskets for military projects from EMI/RFI shielding silicones that are part of the M83528 Qualified Products Lists (QPL) from the Defense Logistics Agency (DLA), which is part of the U.S. Department of Defense (DoD). These Type A, B, C, D, and K silicones provide offsets to Parker Chomerics CHO-SEAL products. SSP is not a Parker Chomerics distributor.

CHO-SEAL 1215 alternative. SSP2569-65 is a 65-durometer, silver-copper EMI shielding silicone. MIL-DTL-83528 Type A. QPL Listed.

CHO-SEAL 1285 alternative. SSP2368-65 is a 65-durometer silver-aluminum EMI shielding silicone. MIL-DTL-83528 Type B. QPL listed.

CHO-SEAL 1217 alternative. SSP2573-75 is a 75-durometer silver-copper EMI shielding fluorosilicone that meets MIL-DTL-83528 Type C. QPL listed.

CHO-SEAL 1287 and CHO-SEAL 1298 alternative. SSP2486-70 is a 70-durometer silver-aluminum EMI shielding fluorosilicone. MIL-DTL-83528 Type D. QPL listed.

CHO-SEAL 1212 alternative. SSP2571-85 is an 85-durometer silver-copper EMI silicone that meets MIL-DTL-83528 Type K. QPL listed.

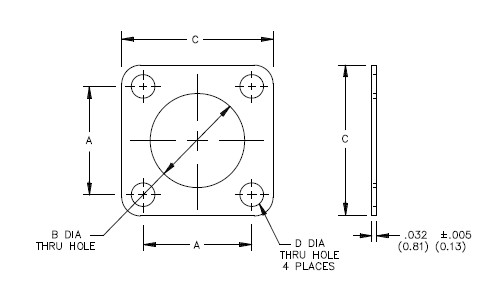

SSP fabricates flange-mount EMI connector gaskets for military connectors in M83528/004 part sizes. Depending on the EMI gasket quantities you need, SSP can use flash cutting or die cutting to produce them.

MIL-DTL-83528 Part Number | Dimensions | Connector Shell Size | |||||||

A | B | C | D | ||||||

M83528/004×001 | .469 | 11.91 | .375 | 9.53 | .738 | 18.75 | .141 | 3.58 | 6 |

M83528/004X002 | .594 | 15.09 | .630 | 16.00 | .840 | 21.34 | .135 | 3.43 | 8 |

M83528/004X003 | .594 | 15.09 | .568 | 14.43 | .812 | 20.62 | .125 | 3.18 | 8 |

M83528/004X004 | .594 | 15.09 | .500 | 12.70 | .875 | 22.23 | .156 | 3.96 | 8 |

M83528/004X005 | .719 | 18.26 | .750 | 19.05 | .965 | 24.51 | .135 | 3.43 | 9,10 |

M83528/004X006 | .719 | 18.26 | .680 | 17.27 | .937 | 23.80 | .125 | 3.18 | 10 |

M83528/004X007 | .719 | 18.26 | .625 | 15.88 | 1.000 | 25.40 | .156 | 3.96 | 10S, SL |

M83528/004X008 | .812 | 20.62 | .875 | 22.23 | 1.060 | 26.92 | .141 | 3.58 | 11,12 |

M83528/004X009 | .813 | 20.65 | .750 | 22.10 | 1.094 | 27.79 | .141 | 3.58 | 12,12S,SL |

M83528/004X010 | .906 | 23.01 | 1.005 | 25.53 | 1.153 | 29.29 | .135 | 3.43 | 13,14 |

M83528/004X011 | .906 | 23.01 | .938 | 23.83 | 1.125 | 28.58 | .125 | 3.18 | 14 |

M83528/004X012 | .906 | 23.01 | .875 | 22.23 | 1.188 | 30.18 | .156 | 3.96 | 14,14S |

M83528/004X013 | .969 | 24.61 | 1.135 | 28.83 | 1.258 | 31.95 | .156 | 3.96 | 15,16 |

M83528/004X014 | .969 | 24.61 | 1.063 | 27.00 | 1.250 | 31.75 | .125 | 3.18 | 16 |

M83528/004X015 | .969 | 24.61 | 1.000 | 25.40 | 1.281 | 32.54 | .156 | 3.96 | 16,16S |

M83528/004X016 | 1.062 | 26.97 | 1.260 | 32.00 | 1.351 | 34.32 | .156 | 3.96 | 17,18 |

M83528/004X017 | 1.062 | 26.97 | 1.189 | 30.20 | 1.343 | 34.11 | .125 | 3.18 | 18 |

M83528/004X018 | 1.062 | 26.97 | 1.135 | 28.83 | 1.375 | 34.93 | .156 | 3.96 | 18,18S |

M83528/004X019 | 1.156 | 29.36 | 1.375 | 34.93 | 1.500 | 38.10 | .141 | 3.58 | 19,20 |

M83528/004X020 | 1.156 | 29.36 | 1.312 | 33.32 | 1.467 | 37.26 | .125 | 3.18 | 20 |

M83528/004X021 | 1.156 | 29.36 | 1.250 | 31.75 | 1.500 | 38.10 | .172 | 4.37 | 20 |

M83528/004X022 | 1.250 | 31.75 | 1.500 | 38.10 | 1.625 | 41.28 | .141 | 3.58 | 21,22 |

M83528/004X023 | 1.250 | 31.75 | 1.437 | 36.50 | 1.562 | 39.67 | .125 | 3.18 | 22 |

M83528/004X024 | 1.250 | 31.75 | 1.375 | 34.93 | 1.625 | 41.28 | .172 | 4.37 | 22 |

M83528/004X025 | 1.375 | 34.93 | 1.625 | 41.28 | 1.750 | 44.45 | .172 | 4.37 | 23,24 |

M83528/004X026 | 1.375 | 34.93 | 1.563 | 39.70 | 1.703 | 43.26 | .152 | 3.86 | 24 |

M83528/004X027 | 1.375 | 34.93 | 1.500 | 38.10 | 1.750 | 44.45 | .203 | 5.16 | 24 |

M83528/004X028 | 1.500 | 38.10 | 1.750 | 44.45 | 1.875 | 47.63 | .172 | 4.37 | 25 |

M83528/004X029 | 1.562 | 39.67 | 1.750 | 44.45 | 2.000 | 50.80 | .203 | 5.16 | 28 |

M83528/004X030 | 1.750 | 44.45 | 2.000 | 50.80 | 2.250 | 57.15 | .219 | 5.56 | 32 |

M83528/004X031 | 1.938 | 49.23 | 2.250 | 57.15 | 2.500 | 63.50 | .219 | 5.56 | 36 |

M83528/004X032 | 2.188 | 55.58 | 2.500 | 63.50 | 2.750 | 69.85 | .219 | 5.56 | 40 |

M83528/004X033 | 2.375 | 60.33 | 2.781 | 70.63 | 3.000 | 76.20 | .219 | 5.56 | 44 |

M83528/004X034 | 2.625 | 66.68 | 3.031 | 76.99 | 3.250 | 82.55 | .219 | 5.56 | 48 |

M83528/004X035 | .500 | 12.70 | .437 | 11.10 | .800 | 20.32 | .135 | 3.43 | |

M83528/004X036 | .500 | 12.70 | .437 | 11.10 | 687 | 17.45 | .135 | 3.43 | |

SSP can also supply with you other types of connector gaskets that provide EMI shielding. Here are some examples.

D-sub connector gaskets are sealing components used with D-subminiature (D-sub) connectors to provide environmental protection and electromagnetic shielding. These gaskets are shaped to fit the D-sub connector flange.

BNC connector gaskets are sealing components used with BNC (Bayonet Neill–Concelman) connectors to provide environmental protection and electromagnetic shielding. They ensure a secure, moisture-resistant, and dust-proof connection.

Circular connector gaskets are sealing components designed for circular connectors, providing environmental protection, EMI shielding, and mechanical stability. These gaskets are positioned between the connector and the mating surface to create a tight seal.

Compression connector gaskets are sealing components designed to create a tight, leak-proof seal between two surfaces when compressed. They prevent leaks, block contaminants, and provide EMI shielding.