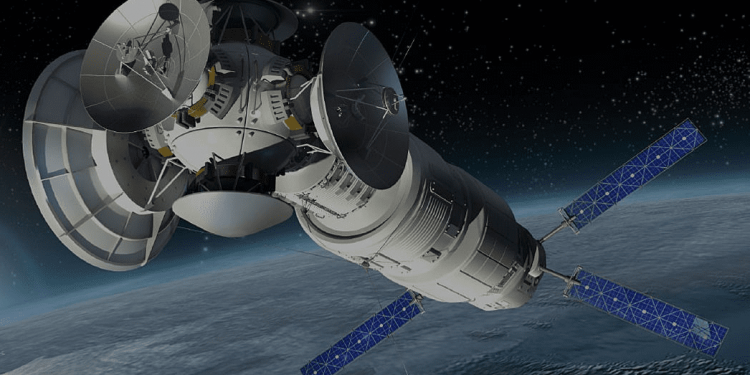

Silicones for space technology are enabling applications ranging from satellite services and space exploration to Earth observation, defense and security, and scientific research. From satellites and ground stations to rockets, spacecraft, and launch services, Tier 1 suppliers like Space X, Blue Origin, and the major defense contractors need silicone gaskets made from specialized materials.

For fabricators who want to provide these high-value products, partnering with the right material supplier is mission-critical. Specialty Silicone Products (SSP) makes silicones that have low levels of outgassing and extreme low-temperature resistance. SSP also manufactures space-grade silicones that provide EMI shielding, including a low-durometer material with UL-94 V0 flame resistance.

Keep reading to learn more and contact SSP if you need the following materials.

Low Outgassing, Low Temperature Silicone with Space Heritage

SSP2575 is a low outgassing, low temperature silicone with a history of use in space programs. This 50-durometer space-grade elastomer remains flexible at -116°C (-177°F). SSP2575 is available as a ready-to-mold compound or as compression molded sheet stock in a range of standard and custom sheet sizes.

Most silicones release gases at low pressures like the near-perfect vacuum of space. This can cloud optics and sensors or interfere with electronics. SSP2575 passes ASTM E595 outgas testing, which is based on the NASA low outgassing standard, and has a Total Mass Loss (TML) of 0.17%. Download the third-party Outgas Report for additional details.

Low Outgassing, Low Temperature Silicone with EMI Shielding

SSP-502-55LT is a low outgassing, low temperature silicone that’s used in EMI gaskets and EMI O-Rings. This 55-durometer EMI shielding silicone has a TR-10 low-temperature capability of -70°C (-94°F). TR-10 is the temperature at which a vulcanizate retracts 10%. The TR Test is part of ASTM D1329, a standard test method for evaluating a rubber’s retraction at low temperatures.

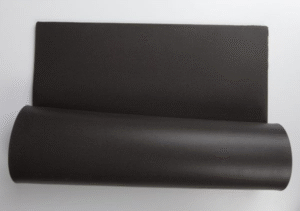

For an electrically conductive silicone, SSP-502-55LT can withstand very low temperatures. This low outgassing silicone passes the ASTM E595 test with a TML of 0.15% and has a shielding effectiveness greater than 113 dB for the 20 MHz to 10 GHz frequency band. Gasket fabricators can choose sheets, rolls, or ready to mold compounds.

Low Outgassing, Low Durometer, Flame-Retardant Silicone with EMI Shielding

SSP-502-40-V0 is a 40-durometer silicone for space technology that combines ASTM E595 low outgassing with proven levels of EMI shielding. It has a UL-94 V0 flame rating, the most stringent rating under the UL-94 standard for the fire testing of polymers. Gasket fabricators can choose sheets or rolls, including slit-width rolls with a pressure sensitive adhesive (PSA) applied.

This independently tested silicone can be used in place of GORE GS2100, a discontinued EMI shielding material from W.L. Gore. Applications for SSP-502-V0 include microwave equipment, high frequency cable connectors, telecommunications equipment, and wireless infrastructure. SSP502-40-V0 has a typical shielding effectiveness of greater than 113 dB for the 20 MHz to 10 GHz band.

Ask SSP for Silicones for Space Technology

Gasket fabricators who pursue opportunities in space technology can gain access to a global market that’s predicted to grow from $512 USD billion in 2025 to USD $978 billion by 2034. SSP supplies the space-grade silicones that fabricators need, and with low minimum order quantities and short lead times.

Contact SSP for more information, and look for us at the Satellite Show (SATSHOW) from March 11 to 13, 2025 in Washington, D.C. (Booth #1051)