EMI connector gaskets provide environmental sealing and shielding against electromagnetic interference (EMI) in electrical and electronic connectors.

They are cut or molded from electrically-conductive elastomers and designed to fill small gaps between uneven connector surfaces. EMI silicones for connector gaskets are soft enough to support compression and can provide proven levels of EMI shielding while resisting water, moisture, many chemicals, and a wide range of temperatures.

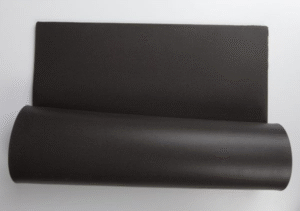

Specialty Silicone Products makes EMI connector gaskets and supplies gasket fabricators with a choice of connector gasket materials, including MIL-DTL-83528 silicones and fluorosilicones. For higher volumes of gaskets, many fabricators use die-cutting to convert SSP’s compression molded sheets or continuous rolls. For prototyping and lower volumes, flash cutting is a good choice because there’s no tooling to pay for or wait for. SSP can flash-cut EMI connector gaskets and we can custom mold EMI gaskets if you need them.

Contact SSP to request a quote

What is an EMI Connector?

An EMI connector (short for Electromagnetic Interference connector) is a type of electrical connector that is specifically designed to reduce or shield against electromagnetic interference (EMI). EMI is unwanted noise or signals that can disrupt the performance of electronic devices, especially in sensitive applications like communications, aerospace, medical devices, and industrial control systems.

Key Features of EMI Connectors

Shielding: They usually have metallic shielding integrated into the design (like metal backshells or gaskets) to block or contain EMI.

Grounding: Good EMI connectors ensure proper grounding, which helps redirect noise away from signal lines.

Filtering: Some EMI connectors may have built-in filters like ferrite beads, capacitors, or other components to suppress high-frequency noise.

Sealing: Often include seals or gaskets that prevent EMI from leaking through gaps between connector parts.

EMI Connector vs. EMI Connector Gasket

EMI connector gaskets are used with EMI connectors and provide shielding and sealing but not grounding and filtering, functions that are performed by other aspects of the EMI connector.

Military Connector Gaskets

There are many different types of connector gaskets, including EMI shielding for D-sub, USB, RF/coax, and power electrical connectors. RF connector types include UHF, TNC, BNC, and SMA – just to name a few. There are also RF connectors for military applications that need to provide EMI shielding that meets U.S. military detail specifications (MIL-DTL). For example, MIL-DTL-83528 contains lettered sections that define the requirements for elastomeric shielding gaskets that contain silver or silver-coated particles.

MIL-DTL-83528 Material Types for Your Connector Gasket

SSP makes EMI silicones and fluorosilicones that meet MIL-DTL-83528 requirements, including several materials that are part of the U.S. military’s Qualified Product List (QPL) for this important specification. The table below describes two of the MIL-DTL-83528 material types that SSP makes. Both are silver-aluminum elastomers, but SSP also makes MIL-DTL-83528 materials with other silver-plated fills.

Type | Description |

B | Silver-plated, aluminum-filled silicone capable of 100 dB of plane wave shielding effectiveness at 10 GHz with a continuous use temperature range of -55°C to +160°C. |

D | Silver-plated, aluminum-filled fluorosilicone capable of 90 dB of plane wave shielding effectiveness at 10 GHz, with, a continuous use temperature range of -55°C to +160°C, and resistant to solvents and jet fuels. |

MIL-DTL-83528 Part Numbers

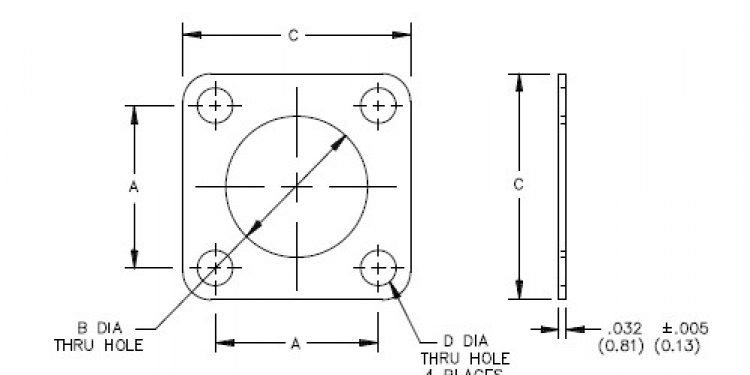

EMI connector gaskets that meet MIL-DTL-83528 requirements have a part identification number (PIN) with four segments. For example, a PIN of M83528/004B001 indicates the following.

- M83528 is the prefix, an abbreviated version of MIL-DTL-83528

- 004 indicates the flange style

- B indicates the material type; in this case, silver-aluminum silicone

- 001 indicates the size and dimensions of the EMI connector gasket

Silver-Aluminum MIL-DTL-83528 Connector Gaskets

The table below describes SSP’s MIL-DTL-83528 connector gaskets that are filled with silver-aluminum particles and that use silicone (Type B) or fluorosilicone (Type D) as the base material. Use these part numbers when ordering flash-cut or molded MIL-DTL-83528 EMI connector gaskets from SSP.

PIN | A | B | C | D | Connector |

M83528/004B001 | .469″ | .375″ | .738″ | .141″ | 6 |

M83528/004B002 | .594″ | .630″ | .840″ | .135″ | 8 |

M83528/004B003 | .594″ | .568″ | .812″ | .125″ | 8 |

M83528/004B004 | .594″ | .500″ | .875″ | .156″ | 8 |

M83528/004B005 | .719″ | .750″ | .965″ | .135″ | 9,10 |

M83528/004B006 | .719″ | .680″ | .937″ | .125″ | 10 |

M83528/004B007 | .719″ | .625″ | 1.000″ | .156″ | 10S,SL |

M83528/004B008 | .812″ | .875″ | 1.060″ | .141″ | 11,12 |

M83528/004B009 | .813″ | .750″ | 1.094″ | .141″ | 12,12S,SL |

M83528/004B010 | .906″ | 1.005″ | 1.153″ | .135″ | 13,14 |

M83528/004B011 | .906″ | .938″ | 1.125″ | .125″ | 14 |

M83528/004B012 | .906″ | .875″ | 1.188″ | .156″ | 14,14S |

M83528/004B013 | .969″ | 1.135″ | 1.258″ | .156″ | 15,16 |

M83528/004B014 | .969″ | 1.063″ | 1.250″ | .125″ | 16 |

M83528/004B015 | .969″ | 1.000″ | 1.281″ | .156″ | 16,16S |

M83528/004B016 | 1.062″ | 1.260″ | 1.351″ | .156″ | 17,18 |

M83528/004B017 | 1.062″ | 1.189″ | 1.343″ | .125″ | 18 |

M83528/004B018 | 1.062″ | 1.135″ | 1.375″ | .156″ | 18,18S |

M83528/004B019 | 1.156″ | 1.375″ | 1.500″ | .141″ | 19,20 |

M83528/004B020 | 1.156″ | 1.312″ | 1.467″ | .125″ | 20 |

M83528/004B021 | 1.156″ | 1.250″ | 1.500″ | .172″ | 20 |

M83528/004B022 | 1.250″ | 1.500″ | 1.625″ | .141″ | 21,22 |

M83528/004B023 | 1.250″ | 1.437″ | 1.562″ | .125″ | 22 |

M83528/004B024 | 1.250″ | 1.375″ | 1.625″ | .172″ | 22 |

M83528/004B025 | 1.375″ | 1.625″ | 1.750″ | .172″ | 23,24 |

M83528/004B026 | 1.375″ | 1.563″ | 1.703″ | .152″ | 24 |

M83528/004B027 | 1.375″ | 1.500″ | 1.750″ | .203″ | 24 |

M83528/004B028 | 1.500″ | 1.750″ | 1.875″ | .172″ | 25 |

M83528/004B029 | 1.562″ | 1.750″ | 2.000″ | .203″ | 28 |

M83528/004B030 | 1.750″ | 2.000″ | 2.250″ | .219″ | 32 |

M83528/004B031 | 1.938″ | 2.250″ | 2.500″ | .219″ | 36 |

M83528/004B032 | 2.188″ | 2.500″ | 2.750″ | .219″ | 40 |

M83528/004B033 | 2.375″ | 2.781″ | 3.000″ | .219″ | 44 |

M83528/004B034 | 2.625″ | 3.031″ | 3.250″ | .219″ | 48 |