Learn how EMI O-Ring bonding from SSP reduces costs and improves performance.

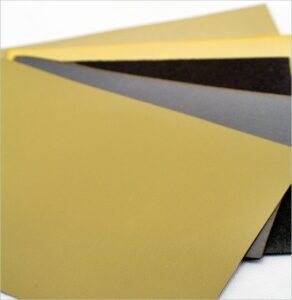

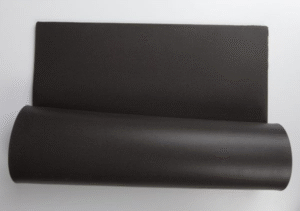

EMI O-rings combine environmental sealing with protection against electromagnetic interference (EMI). They’re made of silicone compounds that are filled with metal or metal-coated particles such as silver, silver-aluminum, or nickel-graphite. Gasket fabricators produce EMI O-rings by cutting EMI cord stock and then bonding the ends of cut lengths together. Applications for these donut-shaped seals include automotive, aerospace, industrial, medical, and military electronics.

To convert EMI cord stock, gasket fabricators can simply measure and cut with a razor blade. After the lengths are cut, the ends are joined together via cold bonding or vulcanization. Specialty Silicone Products (SSP) supplies EMI cord stock to manufacturers and gasket fabricators, but our commitment to your success doesn’t end there. Because we understand your application, we can share our knowledge about the pros and cons of each joining method.

EMI O-Ring Bonding and Cold Bonding

Cold bonding is a joining technique that’s considered to be “cold” because, unlike vulcanization, there’s no heat involved. With cold splicing, a non-conductive adhesive is applied to the cord ends. The absence of compression molding means shorter lead times for your customers, but the advantages don’t end there. Because a skilled worker can cold-bond as many as 200 to 400 EMI O-rings in an eight-hour shift, cold splicing helps to limit your per-part costs.

Cold bonding has some disadvantages, however. If a worker splices an EMI O-ring incorrectly, the non-conductive adhesive may permit the passage of certain frequencies where the ends are joined together. With EMI fluorosilicones, cold bonding can be challenging because of the chemical resistance of the base material. Cold spliced EMI O-rings provide reliable shielding for most applications, but gasket fabricators need to ensure that employees know how to cold-bond EMI O-rings with speed and precision.

Vulcanization and EMI O-Rings

Vulcanization is a joining process that uses heat and pressure to join the ends of cut lengths. Unlike cold bonding, vulcanization uses conductive adhesives. These heat-activated adhesives are applied to the cut ends, which are then pressed together in a hot mold or vulcanizing press. Engineers like the reliability that vulcanized EMI O-rings provide and compare them to die cut EMI gaskets. Plus, vulcanized bonds typically meet or exceed the strength of the material itself.

Vulcanized EMI O-rings have some disadvantages, however. Compared to cold bonding, the lead times are longer and the tooling costs are higher. Because compression molding is required, the per-part cost of a vulcanized EMI O-Ring is more expensive. Many part drawings specify vulcanized O-Rings, however, so engineers need to balance all of a project’s requirements in order to select the most appropriate joining method for their application.

Find EMI Cord Stock for Bonded Rings

Specialty Silicone Products (SSP) supplies EMI cord stock that you can cut and splice using different methods. To place an order or for more information, contact SSP on-line or email Dominic Testo.