Appleton Marine designs and manufactures cranes, winches, windlasses, capstans, and custom designed equipment for commercial marine, offshore oil, and government applications. The Appleton, Wisconsin company also supports the U.S. Navy, which needs gaskets that combine reliable environmental resistance in marine environments with proven levels of shielding against electromagnetic interference (EMI). MIL-DTL-83528, a U.S. military specification, defines requirements for conductive shielding gaskets.

The Problem: EMI Shielding Levels

When a U.S. Navy project required EMI testing to MIL-DTL-83528, engineers from Appleton Marine visited D.L.S. Electronic Systems, Inc. The Wheeling, Illinois company provides EMI testing and consulting services for military and other applications and operates a facility that is accredited by ANAB, the ANSI National Accreditation Board. D.L.S. Electronic Systems also provides independent testing for EMI gasket materials, including conductive elastomers made by Specialty Silicone Products (SSP) of Ballston Spa, New York.

During EMI testing, the D.L.S. team determined that a product did not provide adequate EMI shielding. D.L.S. recommended that Appleton contact SSP, which reviewed the application and found a solution: SSP-502-65, a nickel-graphite filled silicone that has been tested by D.L.S to MIL-DTL-83528. The third-party shielding report for this material is available on SSP’s website, where engineers and buyers can also find the technical data sheet, safety data sheet, and a third-party salt spray test report.

The Solution: MIL-DTL-93528 D-Shape EMI Gaskets

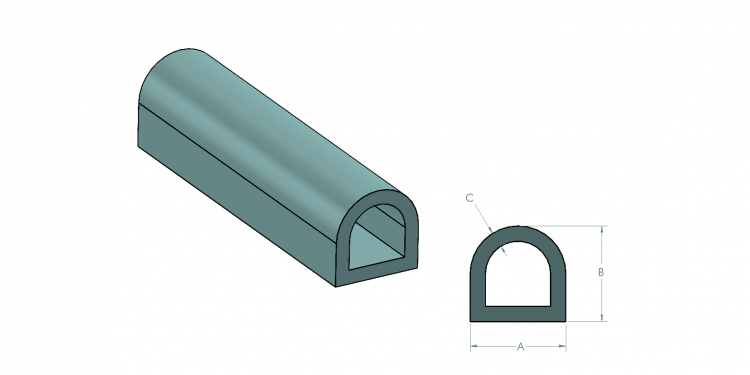

To meet Appleton Marine’s application requirements, SSP extruded SSP-502-65 into an .846” x .427” x .053” Mushroom D-shape and attached PSA 3M9731, a pressure sensitive adhesive (PSA) double-coated tape made by 3M™. SSP then shipped the EMI extrusion to D.L.S. Electronic Systems within two days. Apple Marine received and installed the EMI gasket, and the D.L.S. team determined that MIL-DTL-83528 shielding requirements were met.

SSP-502-65 is 65-durometer EMI silicone that has a minimum attenuation level of 113 dB at 20 MHz and a best-case attenuation level of 141 dB at 200 MHz, according to the D.L.S. test report on SSP’s website. This nickel-graphite elastomer also has silver-like electrical conductivity without the price volatility associated with silver. With its proven salt spray resistance, SSP-502-65 is a good choice for marine applications. SSP-502-65 can be used instead of CHO-SEAL® 6305, a product made by Parker Chomerics.

Along with proven performance, SSP’s EMI silicones have low minimum order quantities (MOQs) and short lead times. SSP sends certificates of analysis (COAs) that prove the quality of its materials and can also provide certificates of conformance (COCs) for applications that require them.

MIL-DTL-83528 D-Shape EMI Gaskets from SSP

For more information about SSP-502-65 or any of SSP’s EMI silicones, contact SSP on-line or email Dominic Testo, SSP’s Business Development Manager.