Specialty Silicone Products (SSP) is focused on lighting fast response times, in-depth customer education, and creative cost-saving ideas in 2025. Whether you’ve worked with us in the past or are learning about us for the first time, the things we’re focused on this year are all designed to help make your business better.

Lightning-Fast Response Times

SSP takes pride in not making you wait for technical support, price quotes, or requests for information. We know you don’t have time to waste when your own customers are asking for an answer. With our recent growth in sales and customer care, we’re ready to gather and send information rapidly. It’s our goal to be the both the strongest link in your supply chain and the fastest.

In-Depth Customer Education

Winning or losing business is about paying attention to details early in the sales process. That’s why SSP’s Technical Sales Team is committed to making sure that our customers and partners get the information they need in a prompt, complete, and easy-to-understand way. Why settle for a supplier that provides a level of service that’s less than what you give to your own customers?

Let’s say you need a spec-grade silicone for an aerospace OEM. It’s easy enough to get a price, but is the material truly compliant with the spec? At SSP, we provide a batch-level Certificate of Analysis (COA) for our A-A-59588 silicones, AMS silicones, and MIL-DTL-25988 fluorosilicones at no extra charge. Along with our quote, we can provide you with a sample COA to help you win the business.

Creative Cost-Saving Ideas

By their very nature, the advanced materials that SSP makes are more expensive than commodity elastomers. At the same time, inflation has hit every industry hard over the past few years. That’s why we’re committed to helping you find creative ways to get the niche materials you need while reducing costs – and without compromising performance.

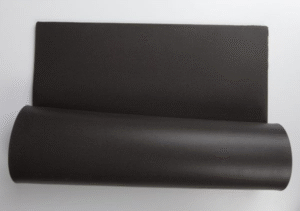

Let’s say you need to die-cut EMI frame gaskets from silicone sheets that contain very expensive silver particles. You could buy full EMI sheets and discard the material in the middle, but the waste would be significant and expensive. When you partner with SSP, however, we can provide you with bonded blank frames that reduce material costs and increase yields.

Consider another example. Let’s say you need to fabricate EMI gaskets that are 8.4 inches wide. Continuous rolls are cost-effective, but not if you’re failing to maximize material yields. If you buy a standard 12-inch-wide roll, you’ll waste a significant amount of material. SSP makes EMI rolls in custom sizes, however, so we can offer you a 9-inch-wide roll instead.

Finally, what if you need to mold 10 parts for a qualification run? Most suppliers will offer you a minimum order quantity (MOQ) of 50 lbs., which is a lot more than you need. When you partner with SSP, however, we can make you a 5-lb. lab batch instead.

Start Strong in 2025

SSP’s focus on lighting fast response times, in-depth customer education, and creative cost-saving ideas can help you get off to a strong start in 2025. Whether you need EMI/RFI silicones, military and aerospace silicones, USP Class VI medical silicones, or products like EMI O-rings or gaskets, we invite you to contact us.