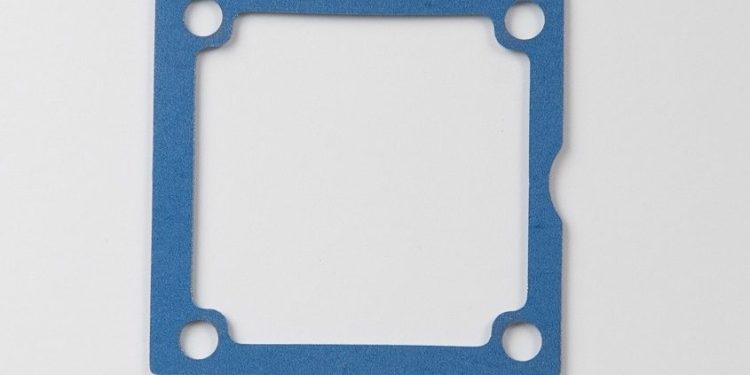

Do you need a silicone gasket for EMI shielding? Among its advantages, silicone rubber is flexible, weather-resistant, and can withstand a wide range of temperatures. Silicones for custom rubber gaskets are also available in lower (softer) durometers, even when they contain electrically contain fillers such as silver-coated or nickel-graphite particles.

Composites and Costs

A silicone gasket for EMI shielding is made of a composite material. Typically, the base is polydimethylsiloxane (PDMS). To this base elastomer, conductive fillers are added. The choice of filler determines the level of electrical conductivity, mechanical properties, and cost of the final product.

Electrical Characteristics of a Silicone Gasket for EMI Shielding

A silicone gasket for EMI shielding can exhibit a wide range of volume resistivity (VR), typically from 10³ to 10⁻³ ohm·cm, depending on the filler concentration and type. The percolation threshold, the minimum amount of conductive filler required to create a conductive path, is critical.

Beyond this threshold, electrical conductivity increases significantly. Fine-tuning the filler concentration is essential to achieve the desired balance between electrical conductivity and mechanical flexibility. SSP offers many standard EMI silicones, and we also have custom formulation capabilities that include compression molding, flash cutting, and die cutting.

Mechanical and Thermal Properties

A silicone gasket for EMI shielding maintains excellent mechanical resilience even after the addition of conductive fillers. The gasket remains highly flexible, with typical elongations at break exceeding 100%. It can also operate across a wide temperature range, typically from -55°C to 200°C. Conductive silicone rubber also retains its outstanding weatherability, UV resistance, and chemical inertness.

Manufacturing and Curing a Silicone Gasket for EMI Shielding

The manufacturing of a silicone gasket for EMI shielding begins with compounding, where the conductive filler is thoroughly mixed into the silicone base. This step must ensure a uniform dispersion of particles to maintain consistent electrical properties. Following compounding, rubber manufacturing techniques are used to shape the material.

There are two main curing methods for conductive silicone rubber:

- Addition-cure (platinum-catalyzed) systems offer vulcanization with minimal shrinkage.

- Peroxide-cure systems are generally used for high-temperature applications but can leave byproducts that affect conductivity.

Quality Control – and Next Steps

For critical applications—such as EMI gaskets for aerospace systems—stringent quality control during manufacturing is essential. Voids, agglomerations of filler, or incomplete curing can affect both electrical conductivity and mechanical integrity.

Specialty Silicones Products is a Made in USA manufacturer with an ISO 9001:2015 certified quality systems. If you need a silicone gasket for EMI shielding, please contact us.