SSP2543 is a 20-durometer AMS silicone that meets the requirements of the AMS 3332 specification from SAE international. This heat-cured elastomer uses a varox peroxide catalyst system.

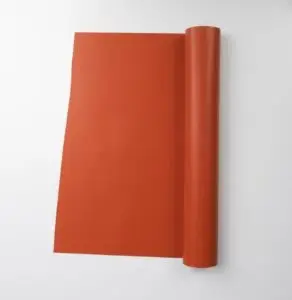

SSP supplies this aerospace silicone as a ready-to-mold compound that can be pigmented to a customer’s requirement. The most popular color is red.

The AMS 3332 specification covers an extreme low-temperature-resistant silicone rubber in the form of sheet, strip, and molded shapes. SAE International, a professional association and standards-developing organization, defines Aerospace Material Specifications (AMS) like AMS 3332.

The table below contains information from the technical data sheet for SSP2534.

Property | Typical Values |

| Shore A (15-30 range) | 20 |

| Tensile Strength (400 psi minimum) | 900 psi |

| Elongation % (350 % minimum) | 850% |

| Tear B (30 ppi min) | 75 ppi |

| Specific Gravity | 1.09-1.15 |

Other tests performed in accordance with the AMS 3332 specification include:

The shelf life for uncatalyzed SSP1773 is indefinite, but this aerospace silicone may need freshening after 1 to 2 years. When catalyzed, the shelf life is 6 months. Cold storage will extend the shelf life for this AMS 3332 silicone.

Download the SSP2534 data sheet and compare this PDF to the AMS 3332 specs from SAE International.

Contact SSP to request a quote, or for additional information about this silicone rubber.