SSP083

SSP083 is a 60-durometer, peroxide-catalyzed, heat-cured fluorosilicone elastomer that meets SAE AMS 3326 and MIL-DTL-25988-(C), Type 2 Class 1 Gr 60 requirements. Find out if this silicone rubber is right for your application.

SSP makes MIL-DTL-25988, Type 2, Class 1 and 2 fluorosilicones. Choose sheets, rolls, extrusions, or ready-to-mold compounds.

MIL-DTL-25988 is a U.S. military specification that supercedes MIL-R-25988. Older prints may reference SAE-MIL-R-25988, AMS-R-25988, AMS-R-25988B, or AMS 25988.

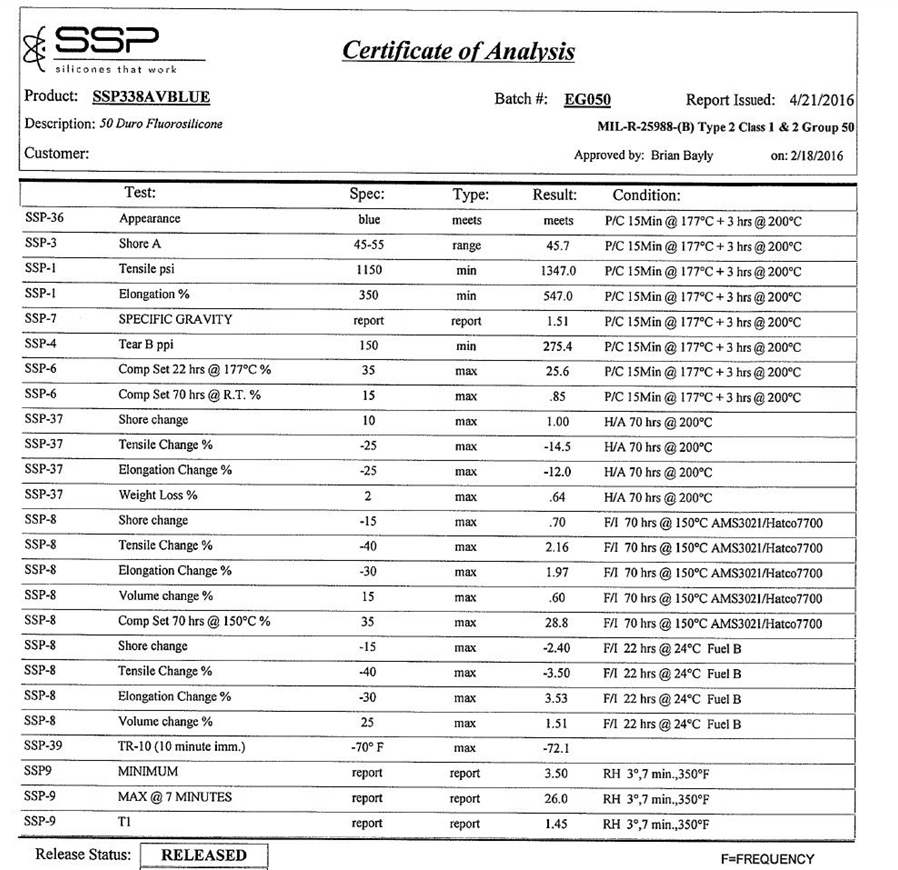

Concerned about traceability? SSP offers a full Certificate of Analysis (COA) for every batch of material that we make.

MIL-DTL-25988 is a U.S. military detail specification that supercedes MIL-R-25988. It divides compliant fluorosilicones into Type 1 materials for O-Rings and Type 2 materials for molded parts, sheets, strips, and extruded shapes. Within each Type, there are two different classes. Class 1 compounds are for general-purpose use, and Class 2 materials are higher-strength elastomers.

SSP makes Type 1, Class 1 and 2 MIL-DTL-25988 fluorosilicones and supplies them as ready-to-mold compounds, continuous rolls, sheet materials, and extrusions. The table below lists our products. All fluorosilicones are peroxide-catalyzed and heat-cured. For traceability, SSP offers a full certificate of analysis (COA) with every batch.

|

SSP Fluorosilicone |

MIL-DTL-25988 Callouts |

Product Specifications |

|||||

|

Product No. |

Type |

Class |

Grade |

Durometer (Shore A) |

Tensile Strength (psi) |

Elongation (%) |

Tear B (ppi/min) |

|

2 |

1 |

40 |

40 |

1500 |

500 |

130 |

|

|

2 |

1 |

50 |

50 |

1300 |

500 |

225 |

|

|

* SSP083 also meets SAE AMS 3326 |

2 |

1 |

60 |

60 |

1000 |

350 |

150 |

|

2 |

1 |

70 |

70 |

1000 |

250 |

128 |

|

|

2 |

1 |

80 |

80 |

800 |

170 |

102 |

|

|

|

2 | 2 | 75 | 75 | 900 | 150 | 150 |

The table below provide additional information about SSP’s Type 2, Class 1 MIL-DTL-25988 fluorosilicones.

SSP083 is a 60-durometer, peroxide-catalyzed, heat-cured fluorosilicone elastomer that meets SAE AMS 3326 and MIL-DTL-25988-(C), Type 2 Class 1 Gr 60 requirements. Find out if this silicone rubber is right for your application.

SSP100 is a 70-durometer, peroxide-catalyzed, heat-cured fluorosilicone elastomer that meets MIL-R-25988B, Type 2, Class 1, Grade 70 requirements. Find out if this silicone rubber is right for your application.

SSP267 is a 40-durometer, peroxide-catalyzed, heat-cured fluorosilicone elastomer that meets MIL-R-25988B, Type 2, Class 1, Grade 40 requirements. Find out if this silicone rubber is right for your application.

SSP338 is a 50-durometer, peroxide-catalyzed, heat-cured fluorosilicone elastomer that meets MIL-R-25988B, Type 2, Class 1, Grade 50 requirements. Find out if this silicone rubber is right for your application.

SSP372 is an 80-durometer, peroxide-catalyzed, heat-cured fluorosilicone elastomer that meets MIL-R-25988B, Type 2, Class 1, Grade 80 requirements. Find out if this silicone rubber is right for your application.

The table below provide additional information about SSP’s Type 2, Class 2 MIL-DTL-25988 fluorosilicones.

SSP082 is a 75-durometer, peroxide-catalyzed, heat-cured fluorosilicone elastomer that meets MIL-R-25988B, Type 2, Class 2, Grade 75 requirements. Find out if this silicone rubber is right for your application.

Each batch of SSP fluorosilicones is fully-certified, and we provide full traceability throughout the supply chain. As the sample COA below shows, SSP’s performs a complete series of tests to demonstrate that a product complies with MIL-R-25988 (MIL-DTL-83528) requirements.

MIL-DTL-25988 is a U.S. military detail (DTL) specification that covers fluorosilicones for aircraft and aviation applications. With their fluorine additions, these silicone elastomers resist petroleum-based fuels and oils, solvents, and harsh chemicals.

MIL-DTL-25988 fluorosilicones also withstand a wide range of temperatures and maintain their tear and tensile strength when immersed in jet fuel. These fuel-resistant materials can withstand repeated flexing without stress cracking and remain flexible and rubbery.

The MIL-DTL-25988 specification divides compliant fluorosilicones into different types, classes, and grades.

Type | Class | Grade |

2 | 2 | 70 |

2 | 1 | 60 |

1 & 2 | 2 | 70 |

2 | 1 | 40 |

2 | 1&2 | 50 |

2 | 1 | 80 |

MIL-DTL-25988C was published in August 2006, and MIL-DTL-25988D was published in 2021. The U.S. Air Force Research Laboratory (AFRL) grandfathered Revision C fluorosilicones until 2022 but then determined that no suppliers could meet the requirements of the newer Revision D specification.

The U.S. Department of Defense (DoD) then adopted a version of an SAE International standard with technical requirements that match MIL-DTL-25988C. The SAE Standard, AMS-R-25988, supersedes MIL-DTL-25988 and meets MIL-DTL-25988C requirements.

See this PDF of an AFRL presentation for more information.