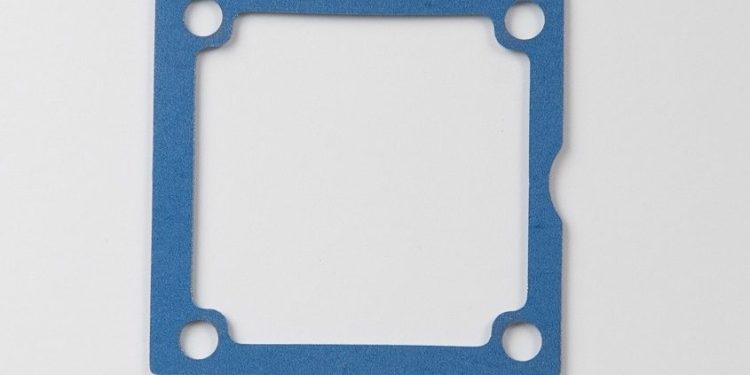

What’s the fastest way to fabricate a flat EMI gasket? Die cutting is quick and efficient at higher volumes, but there’s tooling to wait for. If you need low to medium volumes instead, have you considered flash cutting? This computer-controlled cutting process uses standard knives instead of specialized tools and is one of several EMI gasket fabrication methods that Specialty Silicone Products (SSP) offers. It’s great for rapid prototyping and has many other advantages as well.

Flash Cutting’s Advantages

Flash cutting offers these key advantages for tool-less EMI gasket fabrication.

- No tooling costs: Flash cutting eliminates the need for steel-rule dies, which makes it cost-effective for EMI gasket prototyping and low-volume production.

- Rapid prototyping: Flash cutting’s ability to use your computer-aided design (CAD) files supports new product development and multiple design iterations.

- Accuracy and precision: Flash cutting can achieve tight tolerances and produce smooth edges for a high degree of accuracy and precision.

- Complex shapes and intricate designs: This computer-controlled cutting method isn’t just for simple shapes. It supports design complexity and provides part-to-part consistency.

- Faster turnaround times: Because there’s no tooling to wait for, flash cutting can begin soon after your order arrives for faster turnaround times overall.

- Reduce waste: Flash cutting supports parts nesting for more efficient material usage. EMI silicones aren’t commodity elastomers, and less material waste helps control costs.

Flash Cutting vs. Water Jet Cutting vs. Laser Cutting

How does flash cutting compare to other tool-less fabrication methods for EMI gaskets? Along with clean edges and precise shapes, you’ll get tolerances that are comparable to water jet cutting – another tool-less process. Water jet cutting may be a better option for thick or heat-sensitive materials, but EMI sheets aren’t especially thick, and silicones can withstand higher temperatures than other elastomers.

Laser cutting, another tool-less process, is also an option for EMI gasket fabrication. Laser cutting is quick and efficient, but there’s the potential for heat-affected zones that can cause discoloration, burning, or warping. A laser’s power affects how quickly it can cut, and detailed cuts typically require slower speeds. Water jet cutting won’t cause heat-affected zones, of course, but it’s generally not as fast as flash cutting.

Ask SSP About EMI Gasket Fabrication Without Tooling

Do you need rapid prototypes or low-to-medium volumes of EMI gasketing? SSP offers die-cutting for higher volumes, and we have an in-house machine shop that can produce tooling more quickly than from an outsourced service. Contact SSP to discuss your application, and we’ll recommend the right method for your EMI gasket fabrication project.