MIL-DTL-83528 Type A

CHO-SEAL 1215 alternative. SSP2569-65 is a 65-durometer, silver-copper EMI shielding silicone. MIL-DTL-83528 Type A. QPL Listed.

SSP makes military connector gaskets in M8352/004 part numbers (slash sizes). These EMI gaskets are available with low minimum order quantities and fast turnaround times.

SSP makes its own EMI shielding silicones and has an in-house toolroom, where we machine and maintain molds, tools, dies, jigs, and fixtures. Our MIL-DTL-83528 Type A, B, C, D, and K elastomers are part of the Defense Logistics Agency’s Qualified Product (QPL) List.

Compare our M83528 QPL certified materials to Parker Chomerics CHO-SEAL and Nolato Jabar products. We offer lower minimum order quantities and faster lead times than you’ll find elsewhere. Plus, you can buy from us directly.

SSP makes M83528/004 connector gaskets from EMI/RFI shielding silicones that are part of the M83528 Qualified Products Lists (QPL) from the U.S. Defense Logistics Agency (DLA). SSP’s Type A, B, C, D, and K elastomers provide offsets to Parker Chomerics CHO-SEAL and Nolato Jabar products. Whether your volumes are large or small, we offer a choice of fabrication methods.

As a vertically integrated manufacturer, SSP has it own toolroom so that we don’t have to wait for outsourced molds, tools, jigs, or fixtures. The following section describes the MIL-DTL-83528 Certified materials that we offer.

CHO-SEAL 1215 alternative. SSP2569-65 is a 65-durometer, silver-copper EMI shielding silicone. MIL-DTL-83528 Type A. QPL Listed.

CHO-SEAL 1285 alternative. SSP2368-65 is a 65-durometer silver-aluminum EMI shielding silicone. MIL-DTL-83528 Type B. QPL listed.

CHO-SEAL 1217 alternative. SSP2573-75 is a 75-durometer silver-copper EMI shielding fluorosilicone that meets MIL-DTL-83528 Type C. QPL listed.

CHO-SEAL 1287 and CHO-SEAL 1298 alternative. SSP2486-70 is a 70-durometer silver-aluminum EMI shielding fluorosilicone. MIL-DTL-83528 Type D. QPL listed.

CHO-SEAL 1212 alternative. SSP2571-85 is an 85-durometer silver-copper EMI silicone that meets MIL-DTL-83528 Type K. QPL listed.

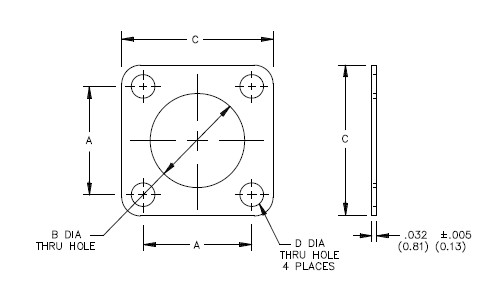

SSP fabricates flange-mount EMI connector gaskets for military connectors in M83528/004 part sizes. Depending on the EMI gasket quantities you need, SSP can use flash cutting or die cutting to produce them.

MIL-DTL-83528 Part Number | Dimensions | Connector Shell Size | |||||||

A | B | C | D | ||||||

M83528/004×001 | .469 | 11.91 | .375 | 9.53 | .738 | 18.75 | .141 | 3.58 | 6 |

M83528/004X002 | .594 | 15.09 | .630 | 16.00 | .840 | 21.34 | .135 | 3.43 | 8 |

M83528/004X003 | .594 | 15.09 | .568 | 14.43 | .812 | 20.62 | .125 | 3.18 | 8 |

M83528/004X004 | .594 | 15.09 | .500 | 12.70 | .875 | 22.23 | .156 | 3.96 | 8 |

M83528/004X005 | .719 | 18.26 | .750 | 19.05 | .965 | 24.51 | .135 | 3.43 | 9,10 |

M83528/004X006 | .719 | 18.26 | .680 | 17.27 | .937 | 23.80 | .125 | 3.18 | 10 |

M83528/004X007 | .719 | 18.26 | .625 | 15.88 | 1.000 | 25.40 | .156 | 3.96 | 10S, SL |

M83528/004X008 | .812 | 20.62 | .875 | 22.23 | 1.060 | 26.92 | .141 | 3.58 | 11,12 |

M83528/004X009 | .813 | 20.65 | .750 | 22.10 | 1.094 | 27.79 | .141 | 3.58 | 12,12S,SL |

M83528/004X010 | .906 | 23.01 | 1.005 | 25.53 | 1.153 | 29.29 | .135 | 3.43 | 13,14 |

M83528/004X011 | .906 | 23.01 | .938 | 23.83 | 1.125 | 28.58 | .125 | 3.18 | 14 |

M83528/004X012 | .906 | 23.01 | .875 | 22.23 | 1.188 | 30.18 | .156 | 3.96 | 14,14S |

M83528/004X013 | .969 | 24.61 | 1.135 | 28.83 | 1.258 | 31.95 | .156 | 3.96 | 15,16 |

M83528/004X014 | .969 | 24.61 | 1.063 | 27.00 | 1.250 | 31.75 | .125 | 3.18 | 16 |

M83528/004X015 | .969 | 24.61 | 1.000 | 25.40 | 1.281 | 32.54 | .156 | 3.96 | 16,16S |

M83528/004X016 | 1.062 | 26.97 | 1.260 | 32.00 | 1.351 | 34.32 | .156 | 3.96 | 17,18 |

M83528/004X017 | 1.062 | 26.97 | 1.189 | 30.20 | 1.343 | 34.11 | .125 | 3.18 | 18 |

M83528/004X018 | 1.062 | 26.97 | 1.135 | 28.83 | 1.375 | 34.93 | .156 | 3.96 | 18,18S |

M83528/004X019 | 1.156 | 29.36 | 1.375 | 34.93 | 1.500 | 38.10 | .141 | 3.58 | 19,20 |

M83528/004X020 | 1.156 | 29.36 | 1.312 | 33.32 | 1.467 | 37.26 | .125 | 3.18 | 20 |

M83528/004X021 | 1.156 | 29.36 | 1.250 | 31.75 | 1.500 | 38.10 | .172 | 4.37 | 20 |

M83528/004X022 | 1.250 | 31.75 | 1.500 | 38.10 | 1.625 | 41.28 | .141 | 3.58 | 21,22 |

M83528/004X023 | 1.250 | 31.75 | 1.437 | 36.50 | 1.562 | 39.67 | .125 | 3.18 | 22 |

M83528/004X024 | 1.250 | 31.75 | 1.375 | 34.93 | 1.625 | 41.28 | .172 | 4.37 | 22 |

M83528/004X025 | 1.375 | 34.93 | 1.625 | 41.28 | 1.750 | 44.45 | .172 | 4.37 | 23,24 |

M83528/004X026 | 1.375 | 34.93 | 1.563 | 39.70 | 1.703 | 43.26 | .152 | 3.86 | 24 |

M83528/004X027 | 1.375 | 34.93 | 1.500 | 38.10 | 1.750 | 44.45 | .203 | 5.16 | 24 |

M83528/004X028 | 1.500 | 38.10 | 1.750 | 44.45 | 1.875 | 47.63 | .172 | 4.37 | 25 |

M83528/004X029 | 1.562 | 39.67 | 1.750 | 44.45 | 2.000 | 50.80 | .203 | 5.16 | 28 |

M83528/004X030 | 1.750 | 44.45 | 2.000 | 50.80 | 2.250 | 57.15 | .219 | 5.56 | 32 |

M83528/004X031 | 1.938 | 49.23 | 2.250 | 57.15 | 2.500 | 63.50 | .219 | 5.56 | 36 |

M83528/004X032 | 2.188 | 55.58 | 2.500 | 63.50 | 2.750 | 69.85 | .219 | 5.56 | 40 |

M83528/004X033 | 2.375 | 60.33 | 2.781 | 70.63 | 3.000 | 76.20 | .219 | 5.56 | 44 |

M83528/004X034 | 2.625 | 66.68 | 3.031 | 76.99 | 3.250 | 82.55 | .219 | 5.56 | 48 |

M83528/004X035 | .500 | 12.70 | .437 | 11.10 | .800 | 20.32 | .135 | 3.43 | |

M83528/004X036 | .500 | 12.70 | .437 | 11.10 | 687 | 17.45 | .135 | 3.43 | |

SSP fabricates M83528/004 EMI connector gaskets from SSP2569-65, a QPL certified MIL-DTL-83528 Type A material.

Use SSP2569-65 instead of Parker Chomerics CHO-SEAL 1215.

MIL-DTL-83528 Part Number | Dimensions | Connector Shell Size | |||||||

A | B | C | D | ||||||

M83528/004A001 | .469 | 11.91 | .375 | 9.53 | .738 | 18.75 | .141 | 3.58 | 6 |

M83528/004A002 | .594 | 15.09 | .630 | 16.00 | .840 | 21.34 | .135 | 3.43 | 8 |

M83528/004A003 | .594 | 15.09 | .568 | 14.43 | .812 | 20.62 | .125 | 3.18 | 8 |

M83528/004A004 | .594 | 15.09 | .500 | 12.70 | .875 | 22.23 | .156 | 3.96 | 8 |

M83528/004A005 | .719 | 18.26 | .750 | 19.05 | .965 | 24.51 | .135 | 3.43 | 9,10 |

M83528/004A006 | .719 | 18.26 | .680 | 17.27 | .937 | 23.80 | .125 | 3.18 | 10 |

M83528/004A007 | .719 | 18.26 | .625 | 15.88 | 1.000 | 25.40 | .156 | 3.96 | 10S, SL |

M83528/004A008 | .812 | 20.62 | .875 | 22.23 | 1.060 | 26.92 | .141 | 3.58 | 11,12 |

M83528/004A009 | .813 | 20.65 | .750 | 22.10 | 1.094 | 27.79 | .141 | 3.58 | 12,12S,SL |

M83528/004A010 | .906 | 23.01 | 1.005 | 25.53 | 1.153 | 29.29 | .135 | 3.43 | 13,14 |

M83528/004A011 | .906 | 23.01 | .938 | 23.83 | 1.125 | 28.58 | .125 | 3.18 | 14 |

M83528/004A012 | .906 | 23.01 | .875 | 22.23 | 1.188 | 30.18 | .156 | 3.96 | 14,14S |

M83528/004A013 | .969 | 24.61 | 1.135 | 28.83 | 1.258 | 31.95 | .156 | 3.96 | 15,16 |

M83528/004A014 | .969 | 24.61 | 1.063 | 27.00 | 1.250 | 31.75 | .125 | 3.18 | 16 |

M83528/004A015 | .969 | 24.61 | 1.000 | 25.40 | 1.281 | 32.54 | .156 | 3.96 | 16,16S |

M83528/004A016 | 1.062 | 26.97 | 1.260 | 32.00 | 1.351 | 34.32 | .156 | 3.96 | 17,18 |

M83528/004A017 | 1.062 | 26.97 | 1.189 | 30.20 | 1.343 | 34.11 | .125 | 3.18 | 18 |

M83528/004A018 | 1.062 | 26.97 | 1.135 | 28.83 | 1.375 | 34.93 | .156 | 3.96 | 18,18S |

M83528/004A019 | 1.156 | 29.36 | 1.375 | 34.93 | 1.500 | 38.10 | .141 | 3.58 | 19,20 |

M83528/004A020 | 1.156 | 29.36 | 1.312 | 33.32 | 1.467 | 37.26 | .125 | 3.18 | 20 |

M83528/004A021 | 1.156 | 29.36 | 1.250 | 31.75 | 1.500 | 38.10 | .172 | 4.37 | 20 |

M83528/004A022 | 1.250 | 31.75 | 1.500 | 38.10 | 1.625 | 41.28 | .141 | 3.58 | 21,22 |

M83528/004A023 | 1.250 | 31.75 | 1.437 | 36.50 | 1.562 | 39.67 | .125 | 3.18 | 22 |

M83528/004A024 | 1.250 | 31.75 | 1.375 | 34.93 | 1.625 | 41.28 | .172 | 4.37 | 22 |

M83528/004A025 | 1.375 | 34.93 | 1.625 | 41.28 | 1.750 | 44.45 | .172 | 4.37 | 23,24 |

M83528/004A026 | 1.375 | 34.93 | 1.563 | 39.70 | 1.703 | 43.26 | .152 | 3.86 | 24 |

M83528/004A027 | 1.375 | 34.93 | 1.500 | 38.10 | 1.750 | 44.45 | .203 | 5.16 | 24 |

M83528/004A028 | 1.500 | 38.10 | 1.750 | 44.45 | 1.875 | 47.63 | .172 | 4.37 | 25 |

M83528/004A029 | 1.562 | 39.67 | 1.750 | 44.45 | 2.000 | 50.80 | .203 | 5.16 | 28 |

M83528/004A030 | 1.750 | 44.45 | 2.000 | 50.80 | 2.250 | 57.15 | .219 | 5.56 | 32 |

M83528/004A031 | 1.938 | 49.23 | 2.250 | 57.15 | 2.500 | 63.50 | .219 | 5.56 | 36 |

M83528/004A032 | 2.188 | 55.58 | 2.500 | 63.50 | 2.750 | 69.85 | .219 | 5.56 | 40 |

M83528/004A033 | 2.375 | 60.33 | 2.781 | 70.63 | 3.000 | 76.20 | .219 | 5.56 | 44 |

M83528/004A034 | 2.625 | 66.68 | 3.031 | 76.99 | 3.250 | 82.55 | .219 | 5.56 | 48 |

M83528/004A035 | .500 | 12.70 | .437 | 11.10 | .800 | 20.32 | .135 | 3.43 | |

M83528/004A036 | .500 | 12.70 | .437 | 11.10 | 687 | 17.45 | .135 | 3.43 | |

SSP fabricates M83528/004 EMI connector gaskets from SSP2368-65, a QPL certified MIL-DTL-83528 Type B material.

Use SSP2368-65 instead of Parker Chomerics CHO-SEAL 1285.

MIL-DTL-83528 Part Number | Dimensions | Connector Shell Size | |||||||

A | B | C | D | ||||||

M83528/004B001 | .469 | 11.91 | .375 | 9.53 | .738 | 18.75 | .141 | 3.58 | 6 |

M83528/004B002 | .594 | 15.09 | .630 | 16.00 | .840 | 21.34 | .135 | 3.43 | 8 |

M83528/004B003 | .594 | 15.09 | .568 | 14.43 | .812 | 20.62 | .125 | 3.18 | 8 |

M83528/004B004 | .594 | 15.09 | .500 | 12.70 | .875 | 22.23 | .156 | 3.96 | 8 |

M83528/004B005 | .719 | 18.26 | .750 | 19.05 | .965 | 24.51 | .135 | 3.43 | 9,10 |

M83528/004B006 | .719 | 18.26 | .680 | 17.27 | .937 | 23.80 | .125 | 3.18 | 10 |

M83528/004B007 | .719 | 18.26 | .625 | 15.88 | 1.000 | 25.40 | .156 | 3.96 | 10S, SL |

M83528/004B008 | .812 | 20.62 | .875 | 22.23 | 1.060 | 26.92 | .141 | 3.58 | 11,12 |

M83528/004B009 | .813 | 20.65 | .750 | 22.10 | 1.094 | 27.79 | .141 | 3.58 | 12,12S,SL |

M83528/004B010 | .906 | 23.01 | 1.005 | 25.53 | 1.153 | 29.29 | .135 | 3.43 | 13,14 |

M83528/004B011 | .906 | 23.01 | .938 | 23.83 | 1.125 | 28.58 | .125 | 3.18 | 14 |

M83528/004B012 | .906 | 23.01 | .875 | 22.23 | 1.188 | 30.18 | .156 | 3.96 | 14,14S |

M83528/004B013 | .969 | 24.61 | 1.135 | 28.83 | 1.258 | 31.95 | .156 | 3.96 | 15,16 |

M83528/004B014 | .969 | 24.61 | 1.063 | 27.00 | 1.250 | 31.75 | .125 | 3.18 | 16 |

M83528/004B015 | .969 | 24.61 | 1.000 | 25.40 | 1.281 | 32.54 | .156 | 3.96 | 16,16S |

M83528/004B016 | 1.062 | 26.97 | 1.260 | 32.00 | 1.351 | 34.32 | .156 | 3.96 | 17,18 |

M83528/004B017 | 1.062 | 26.97 | 1.189 | 30.20 | 1.343 | 34.11 | .125 | 3.18 | 18 |

M83528/004B018 | 1.062 | 26.97 | 1.135 | 28.83 | 1.375 | 34.93 | .156 | 3.96 | 18,18S |

M83528/004B019 | 1.156 | 29.36 | 1.375 | 34.93 | 1.500 | 38.10 | .141 | 3.58 | 19,20 |

M83528/004B020 | 1.156 | 29.36 | 1.312 | 33.32 | 1.467 | 37.26 | .125 | 3.18 | 20 |

M83528/004B021 | 1.156 | 29.36 | 1.250 | 31.75 | 1.500 | 38.10 | .172 | 4.37 | 20 |

M83528/004B022 | 1.250 | 31.75 | 1.500 | 38.10 | 1.625 | 41.28 | .141 | 3.58 | 21,22 |

M83528/004B023 | 1.250 | 31.75 | 1.437 | 36.50 | 1.562 | 39.67 | .125 | 3.18 | 22 |

M83528/004B024 | 1.250 | 31.75 | 1.375 | 34.93 | 1.625 | 41.28 | .172 | 4.37 | 22 |

M83528/004B025 | 1.375 | 34.93 | 1.625 | 41.28 | 1.750 | 44.45 | .172 | 4.37 | 23,24 |

M83528/004B026 | 1.375 | 34.93 | 1.563 | 39.70 | 1.703 | 43.26 | .152 | 3.86 | 24 |

M83528/004B027 | 1.375 | 34.93 | 1.500 | 38.10 | 1.750 | 44.45 | .203 | 5.16 | 24 |

M83528/004B028 | 1.500 | 38.10 | 1.750 | 44.45 | 1.875 | 47.63 | .172 | 4.37 | 25 |

M83528/004B029 | 1.562 | 39.67 | 1.750 | 44.45 | 2.000 | 50.80 | .203 | 5.16 | 28 |

M83528/004B030 | 1.750 | 44.45 | 2.000 | 50.80 | 2.250 | 57.15 | .219 | 5.56 | 32 |

M83528/004B031 | 1.938 | 49.23 | 2.250 | 57.15 | 2.500 | 63.50 | .219 | 5.56 | 36 |

M83528/004B032 | 2.188 | 55.58 | 2.500 | 63.50 | 2.750 | 69.85 | .219 | 5.56 | 40 |

M83528/004B033 | 2.375 | 60.33 | 2.781 | 70.63 | 3.000 | 76.20 | .219 | 5.56 | 44 |

M83528/004B034 | 2.625 | 66.68 | 3.031 | 76.99 | 3.250 | 82.55 | .219 | 5.56 | 48 |

M83528/004B035 | .500 | 12.70 | .437 | 11.10 | .800 | 20.32 | .135 | 3.43 | |

M83528/004B036 | .500 | 12.70 | .437 | 11.10 | 687 | 17.45 | .135 | 3.43 | |

SSP fabricates M83528/004 EMI connector gaskets from SSP2573-75, a QPL certified MIL-DTL-83528 Type C material.

Use SSP2573-75 instead of Parker Chomerics CHO-SEAL 1217.

MIL-DTL-83528 Part Number | Dimensions | Connector Shell Size | |||||||

A | B | C | D | ||||||

M83528/004C001 | .469 | 11.91 | .375 | 9.53 | .738 | 18.75 | .141 | 3.58 | 6 |

M83528/004C002 | .594 | 15.09 | .630 | 16.00 | .840 | 21.34 | .135 | 3.43 | 8 |

M83528/004C003 | .594 | 15.09 | .568 | 14.43 | .812 | 20.62 | .125 | 3.18 | 8 |

M83528/004C004 | .594 | 15.09 | .500 | 12.70 | .875 | 22.23 | .156 | 3.96 | 8 |

M83528/004C005 | .719 | 18.26 | .750 | 19.05 | .965 | 24.51 | .135 | 3.43 | 9,10 |

M83528/004C006 | .719 | 18.26 | .680 | 17.27 | .937 | 23.80 | .125 | 3.18 | 10 |

M83528/004C007 | .719 | 18.26 | .625 | 15.88 | 1.000 | 25.40 | .156 | 3.96 | 10S, SL |

M83528/004C008 | .812 | 20.62 | .875 | 22.23 | 1.060 | 26.92 | .141 | 3.58 | 11,12 |

M83528/004C009 | .813 | 20.65 | .750 | 22.10 | 1.094 | 27.79 | .141 | 3.58 | 12,12S,SL |

M83528/004C010 | .906 | 23.01 | 1.005 | 25.53 | 1.153 | 29.29 | .135 | 3.43 | 13,14 |

M83528/004C011 | .906 | 23.01 | .938 | 23.83 | 1.125 | 28.58 | .125 | 3.18 | 14 |

M83528/004C012 | .906 | 23.01 | .875 | 22.23 | 1.188 | 30.18 | .156 | 3.96 | 14,14S |

M83528/004C013 | .969 | 24.61 | 1.135 | 28.83 | 1.258 | 31.95 | .156 | 3.96 | 15,16 |

M83528/004C014 | .969 | 24.61 | 1.063 | 27.00 | 1.250 | 31.75 | .125 | 3.18 | 16 |

M83528/004C015 | .969 | 24.61 | 1.000 | 25.40 | 1.281 | 32.54 | .156 | 3.96 | 16,16S |

M83528/004C016 | 1.062 | 26.97 | 1.260 | 32.00 | 1.351 | 34.32 | .156 | 3.96 | 17,18 |

M83528/004C017 | 1.062 | 26.97 | 1.189 | 30.20 | 1.343 | 34.11 | .125 | 3.18 | 18 |

M83528/004C018 | 1.062 | 26.97 | 1.135 | 28.83 | 1.375 | 34.93 | .156 | 3.96 | 18,18S |

M83528/004C019 | 1.156 | 29.36 | 1.375 | 34.93 | 1.500 | 38.10 | .141 | 3.58 | 19,20 |

M83528/004C020 | 1.156 | 29.36 | 1.312 | 33.32 | 1.467 | 37.26 | .125 | 3.18 | 20 |

M83528/004C021 | 1.156 | 29.36 | 1.250 | 31.75 | 1.500 | 38.10 | .172 | 4.37 | 20 |

M83528/004C022 | 1.250 | 31.75 | 1.500 | 38.10 | 1.625 | 41.28 | .141 | 3.58 | 21,22 |

M83528/004C023 | 1.250 | 31.75 | 1.437 | 36.50 | 1.562 | 39.67 | .125 | 3.18 | 22 |

M83528/004C024 | 1.250 | 31.75 | 1.375 | 34.93 | 1.625 | 41.28 | .172 | 4.37 | 22 |

M83528/004C025 | 1.375 | 34.93 | 1.625 | 41.28 | 1.750 | 44.45 | .172 | 4.37 | 23,24 |

M83528/004C026 | 1.375 | 34.93 | 1.563 | 39.70 | 1.703 | 43.26 | .152 | 3.86 | 24 |

M83528/004C027 | 1.375 | 34.93 | 1.500 | 38.10 | 1.750 | 44.45 | .203 | 5.16 | 24 |

M83528/004C028 | 1.500 | 38.10 | 1.750 | 44.45 | 1.875 | 47.63 | .172 | 4.37 | 25 |

M83528/004C029 | 1.562 | 39.67 | 1.750 | 44.45 | 2.000 | 50.80 | .203 | 5.16 | 28 |

M83528/004C030 | 1.750 | 44.45 | 2.000 | 50.80 | 2.250 | 57.15 | .219 | 5.56 | 32 |

M83528/004C031 | 1.938 | 49.23 | 2.250 | 57.15 | 2.500 | 63.50 | .219 | 5.56 | 36 |

M83528/004C032 | 2.188 | 55.58 | 2.500 | 63.50 | 2.750 | 69.85 | .219 | 5.56 | 40 |

M83528/004C033 | 2.375 | 60.33 | 2.781 | 70.63 | 3.000 | 76.20 | .219 | 5.56 | 44 |

M83528/004C034 | 2.625 | 66.68 | 3.031 | 76.99 | 3.250 | 82.55 | .219 | 5.56 | 48 |

M83528/004C035 | .500 | 12.70 | .437 | 11.10 | .800 | 20.32 | .135 | 3.43 | |

M83528/004C036 | .500 | 12.70 | .437 | 11.10 | 687 | 17.45 | .135 | 3.43 | |

SSP fabricates M83528/004 EMI connector gaskets from SSP2486-70, a QPL certified MIL-DTL-83528 Type D material.

Use SSP2486-70 instead of Parker Chomerics CHO-SEAL 1217 and CHO-SEAL 1298.

MIL-DTL-83528 Part Number | Dimensions | Connector Shell Size | |||||||

A | B | C | D | ||||||

M83528/004D001 | .469 | 11.91 | .375 | 9.53 | .738 | 18.75 | .141 | 3.58 | 6 |

M83528/004D002 | .594 | 15.09 | .630 | 16.00 | .840 | 21.34 | .135 | 3.43 | 8 |

M83528/004D003 | .594 | 15.09 | .568 | 14.43 | .812 | 20.62 | .125 | 3.18 | 8 |

M83528/004D004 | .594 | 15.09 | .500 | 12.70 | .875 | 22.23 | .156 | 3.96 | 8 |

M83528/004D005 | .719 | 18.26 | .750 | 19.05 | .965 | 24.51 | .135 | 3.43 | 9,10 |

M83528/004D006 | .719 | 18.26 | .680 | 17.27 | .937 | 23.80 | .125 | 3.18 | 10 |

M83528/004D007 | .719 | 18.26 | .625 | 15.88 | 1.000 | 25.40 | .156 | 3.96 | 10S, SL |

M83528/004D008 | .812 | 20.62 | .875 | 22.23 | 1.060 | 26.92 | .141 | 3.58 | 11,12 |

M83528/004D009 | .813 | 20.65 | .750 | 22.10 | 1.094 | 27.79 | .141 | 3.58 | 12,12S,SL |

M83528/004D010 | .906 | 23.01 | 1.005 | 25.53 | 1.153 | 29.29 | .135 | 3.43 | 13,14 |

M83528/004D011 | .906 | 23.01 | .938 | 23.83 | 1.125 | 28.58 | .125 | 3.18 | 14 |

M83528/004D012 | .906 | 23.01 | .875 | 22.23 | 1.188 | 30.18 | .156 | 3.96 | 14,14S |

M83528/004D013 | .969 | 24.61 | 1.135 | 28.83 | 1.258 | 31.95 | .156 | 3.96 | 15,16 |

M83528/004D014 | .969 | 24.61 | 1.063 | 27.00 | 1.250 | 31.75 | .125 | 3.18 | 16 |

M83528/004D015 | .969 | 24.61 | 1.000 | 25.40 | 1.281 | 32.54 | .156 | 3.96 | 16,16S |

M83528/004D016 | 1.062 | 26.97 | 1.260 | 32.00 | 1.351 | 34.32 | .156 | 3.96 | 17,18 |

M83528/004D017 | 1.062 | 26.97 | 1.189 | 30.20 | 1.343 | 34.11 | .125 | 3.18 | 18 |

M83528/004D018 | 1.062 | 26.97 | 1.135 | 28.83 | 1.375 | 34.93 | .156 | 3.96 | 18,18S |

M83528/004D019 | 1.156 | 29.36 | 1.375 | 34.93 | 1.500 | 38.10 | .141 | 3.58 | 19,20 |

M83528/004D020 | 1.156 | 29.36 | 1.312 | 33.32 | 1.467 | 37.26 | .125 | 3.18 | 20 |

M83528/004D021 | 1.156 | 29.36 | 1.250 | 31.75 | 1.500 | 38.10 | .172 | 4.37 | 20 |

M83528/004D022 | 1.250 | 31.75 | 1.500 | 38.10 | 1.625 | 41.28 | .141 | 3.58 | 21,22 |

M83528/004D023 | 1.250 | 31.75 | 1.437 | 36.50 | 1.562 | 39.67 | .125 | 3.18 | 22 |

M83528/004D024 | 1.250 | 31.75 | 1.375 | 34.93 | 1.625 | 41.28 | .172 | 4.37 | 22 |

M83528/004D025 | 1.375 | 34.93 | 1.625 | 41.28 | 1.750 | 44.45 | .172 | 4.37 | 23,24 |

M83528/004D026 | 1.375 | 34.93 | 1.563 | 39.70 | 1.703 | 43.26 | .152 | 3.86 | 24 |

M83528/004D027 | 1.375 | 34.93 | 1.500 | 38.10 | 1.750 | 44.45 | .203 | 5.16 | 24 |

M83528/004D028 | 1.500 | 38.10 | 1.750 | 44.45 | 1.875 | 47.63 | .172 | 4.37 | 25 |

M83528/004D029 | 1.562 | 39.67 | 1.750 | 44.45 | 2.000 | 50.80 | .203 | 5.16 | 28 |

M83528/004D030 | 1.750 | 44.45 | 2.000 | 50.80 | 2.250 | 57.15 | .219 | 5.56 | 32 |

M83528/004D031 | 1.938 | 49.23 | 2.250 | 57.15 | 2.500 | 63.50 | .219 | 5.56 | 36 |

M83528/004D032 | 2.188 | 55.58 | 2.500 | 63.50 | 2.750 | 69.85 | .219 | 5.56 | 40 |

M83528/004D033 | 2.375 | 60.33 | 2.781 | 70.63 | 3.000 | 76.20 | .219 | 5.56 | 44 |

M83528/004D034 | 2.625 | 66.68 | 3.031 | 76.99 | 3.250 | 82.55 | .219 | 5.56 | 48 |

M83528/004D035 | .500 | 12.70 | .437 | 11.10 | .800 | 20.32 | .135 | 3.43 | |

M83528/004D036 | .500 | 12.70 | .437 | 11.10 | 687 | 17.45 | .135 | 3.43 | |

SSP fabricates M83528/004 EMI connector gaskets from SSP2571-85, a QPL certified MIL-DTL-83528 Type K material.

Use SSP2571-85 instead of Parker Chomerics CHO-SEAL 1212.

MIL-DTL-83528 Part Number | Dimensions | Connector Shell Size | |||||||

A | B | C | D | ||||||

M83528/004K001 | .469 | 11.91 | .375 | 9.53 | .738 | 18.75 | .141 | 3.58 | 6 |

M83528/004K002 | .594 | 15.09 | .630 | 16.00 | .840 | 21.34 | .135 | 3.43 | 8 |

M83528/004K003 | .594 | 15.09 | .568 | 14.43 | .812 | 20.62 | .125 | 3.18 | 8 |

M83528/004K004 | .594 | 15.09 | .500 | 12.70 | .875 | 22.23 | .156 | 3.96 | 8 |

M83528/004K005 | .719 | 18.26 | .750 | 19.05 | .965 | 24.51 | .135 | 3.43 | 9,10 |

M83528/004K006 | .719 | 18.26 | .680 | 17.27 | .937 | 23.80 | .125 | 3.18 | 10 |

M83528/004K007 | .719 | 18.26 | .625 | 15.88 | 1.000 | 25.40 | .156 | 3.96 | 10S, SL |

M83528/004K008 | .812 | 20.62 | .875 | 22.23 | 1.060 | 26.92 | .141 | 3.58 | 11,12 |

M83528/004K009 | .813 | 20.65 | .750 | 22.10 | 1.094 | 27.79 | .141 | 3.58 | 12,12S,SL |

M83528/004K010 | .906 | 23.01 | 1.005 | 25.53 | 1.153 | 29.29 | .135 | 3.43 | 13,14 |

M83528/004K011 | .906 | 23.01 | .938 | 23.83 | 1.125 | 28.58 | .125 | 3.18 | 14 |

M83528/004K012 | .906 | 23.01 | .875 | 22.23 | 1.188 | 30.18 | .156 | 3.96 | 14,14S |

M83528/004K013 | .969 | 24.61 | 1.135 | 28.83 | 1.258 | 31.95 | .156 | 3.96 | 15,16 |

M83528/004K014 | .969 | 24.61 | 1.063 | 27.00 | 1.250 | 31.75 | .125 | 3.18 | 16 |

M83528/004K015 | .969 | 24.61 | 1.000 | 25.40 | 1.281 | 32.54 | .156 | 3.96 | 16,16S |

M83528/004K016 | 1.062 | 26.97 | 1.260 | 32.00 | 1.351 | 34.32 | .156 | 3.96 | 17,18 |

M83528/004K017 | 1.062 | 26.97 | 1.189 | 30.20 | 1.343 | 34.11 | .125 | 3.18 | 18 |

M83528/004K018 | 1.062 | 26.97 | 1.135 | 28.83 | 1.375 | 34.93 | .156 | 3.96 | 18,18S |

M83528/004K019 | 1.156 | 29.36 | 1.375 | 34.93 | 1.500 | 38.10 | .141 | 3.58 | 19,20 |

M83528/004K020 | 1.156 | 29.36 | 1.312 | 33.32 | 1.467 | 37.26 | .125 | 3.18 | 20 |

M83528/004K021 | 1.156 | 29.36 | 1.250 | 31.75 | 1.500 | 38.10 | .172 | 4.37 | 20 |

M83528/004K022 | 1.250 | 31.75 | 1.500 | 38.10 | 1.625 | 41.28 | .141 | 3.58 | 21,22 |

M83528/004K023 | 1.250 | 31.75 | 1.437 | 36.50 | 1.562 | 39.67 | .125 | 3.18 | 22 |

M83528/004K024 | 1.250 | 31.75 | 1.375 | 34.93 | 1.625 | 41.28 | .172 | 4.37 | 22 |

M83528/004K025 | 1.375 | 34.93 | 1.625 | 41.28 | 1.750 | 44.45 | .172 | 4.37 | 23,24 |

M83528/004K026 | 1.375 | 34.93 | 1.563 | 39.70 | 1.703 | 43.26 | .152 | 3.86 | 24 |

M83528/004K027 | 1.375 | 34.93 | 1.500 | 38.10 | 1.750 | 44.45 | .203 | 5.16 | 24 |

M83528/004K028 | 1.500 | 38.10 | 1.750 | 44.45 | 1.875 | 47.63 | .172 | 4.37 | 25 |

M83528/004K029 | 1.562 | 39.67 | 1.750 | 44.45 | 2.000 | 50.80 | .203 | 5.16 | 28 |

M83528/004K030 | 1.750 | 44.45 | 2.000 | 50.80 | 2.250 | 57.15 | .219 | 5.56 | 32 |

M83528/004K031 | 1.938 | 49.23 | 2.250 | 57.15 | 2.500 | 63.50 | .219 | 5.56 | 36 |

M83528/004K032 | 2.188 | 55.58 | 2.500 | 63.50 | 2.750 | 69.85 | .219 | 5.56 | 40 |

M83528/004K033 | 2.375 | 60.33 | 2.781 | 70.63 | 3.000 | 76.20 | .219 | 5.56 | 44 |

M83528/004K034 | 2.625 | 66.68 | 3.031 | 76.99 | 3.250 | 82.55 | .219 | 5.56 | 48 |

M83528/004K035 | .500 | 12.70 | .437 | 11.10 | .800 | 20.32 | .135 | 3.43 | |

M83528/004K036 | .500 | 12.70 | .437 | 11.10 | 687 | 17.45 | .135 | 3.43 | |