SSP makes EMI connector gaskets for electrical and electronic connectors used in harsh environments and demanding applications.

We make standard and custom products from the EMI silicones we manufacture in Ballston Spa, New York (USA). Many of our materials are MIL-DTL-83528 QPL certified.

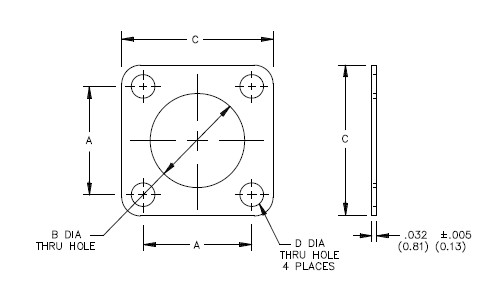

SSP makes connector gaskets in M83528/004 slash sizes. We also offer EMI gaskets for other types of connectors used in defense, aerospace, medical devices, robotics, and unmanned systems.

Compare us to Parker Chomerics CHO-SEAL and Nolato Jabar. SSP offers low minimums and quick turnaround times, and we sell to you directly.

EMI connector gaskets provide environmental sealing and shielding against electromagnetic interference (EMI). They reduce or eliminate the transmission of EMI between connected devices, or through the connector itself. Connector gaskets are cut or molded from elastomers and fill small gaps between uneven connector surfaces.

SSP’s EMI shielding silicones are soft enough to support compression and provide proven levels of shielding while resisting water, moisture, many chemicals, and a wide range of temperatures. They’re also available with low minimum order quantities and quick turnaround times. Plus, we sell to you directly and offer Made in USA manufacturing.

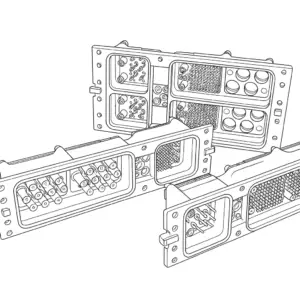

SSP makes these and other types of EMI connector gaskets for military and civilian applications.

Keep reading to learn more and contact us to let us know what you need.

SSP makes M83528/004 military connector gaskets from EMI/RFI shielding silicones that are part of the M83528 Qualified Products Lists (QPL) from the U.S. Defense Logistics Agency (DLA). SSP’s Type A, B, C, D, and K elastomers provide offsets to Parker Chomerics CHO-SEAL and Nolato Jabar products. Whether your volumes are large or small, we offer a choice of fabrication methods.

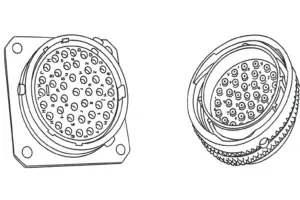

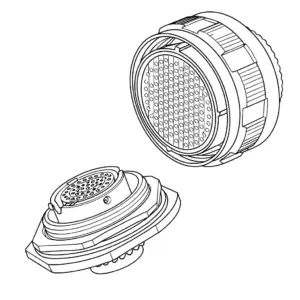

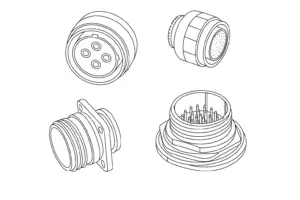

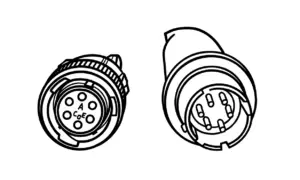

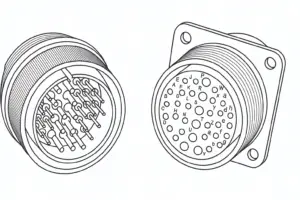

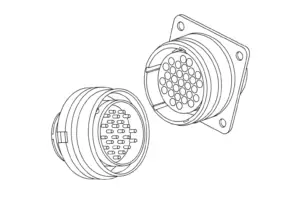

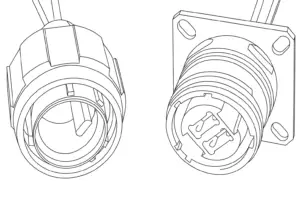

Circular connector gaskets are designed for rugged circular connectors that resist shock vibration, and contaminants. They typically contain a locking mechanism and are used for power, signal, and data transmission in harsh environments.

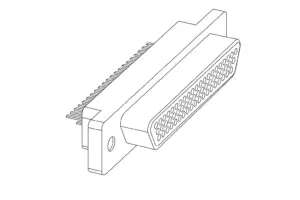

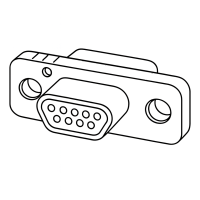

D-subminiature connector gaskets are used with D-subminiature (D-sub) connectors, components for reliable data, signal, and power transmission in computers, industrial control and communication. AMPLIMITE from TE Connectivity is a common brand name for these connectors.

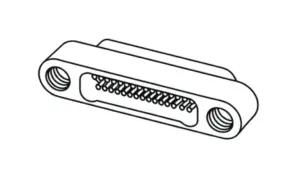

Micro-D connector gaskets are used with Micro-D connectors and provide sealing and shielding in harsh, space-constrained environments. Micro-D connector manufacturers include NICOMATIC, Omnetics, and AvioRace. Defense and aerospace applications include avionics, missiles, and unmanned aerial vehicles (UAVs).

MDM connector gaskets are used with a specific, high-performance line of Micro-D connectors for defense and aerospace applications and may meet MIL-DTL-83513 requirements. MDM connectors are similar to and sometimes interchangeable with Micro-D connectors; however, these components are not the same. MDM connector manufacturers include Glenair and ITT Cannon.

Nano-D connector gaskets are used with Nano D connectors, which feature an ultra-small, D-shaped design. These connectors are used in military, aerospace, satellite, medical, and robotics applications where size, weight, and power (SWaP) are critical. They are significantly smaller than Micro-D and standard D-sub connectors and may meet MIL-DTL-32139 standards. Omnetics is a leading Nano-D connector manufacturer.

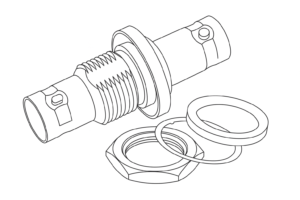

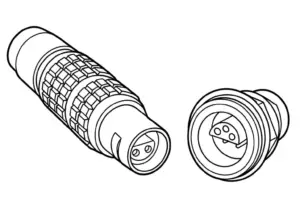

BNC connector gaskets are used with BNC connectors and feature a secure, twist-to-lock mechanism. They are used in RF applications such as computer networking and video transmissions, and in industrial test equipment like oscilloscopes. Their bayonet locking mechanism ensures a vibration-resistant connection that snaps into place quickly and is also easy to disconnect.

NASA spec connectors, also known as space-grade connectors, are designed and qualified to meet the requirements of space applications on spacecraft and satellites. They are built to withstand harsh conditions like extreme temperatures, shock, and vibration, and must pass stringent tests for properties like outgassing and residual magnetism, which could interfere with other equipment.

MIL-C-38999 connector gaskets are miniature, circular connectors for reliable connections in harsh environments with extreme temperatures, vibration, moisture, and corrosion. They are used with MIL-C-38999 connectors, which are now known as MIL-DTL-38999 connectors. MIL-DTL-38999 connector gaskets feature secure coupling mechanisms and are used with aircraft, ships, tanks, and satellites.

MIL-C-26482 connector gaskets are specialized components for miniature, circular, bayonet-style military connectors. Applications for MIL-C-26482 connectors include military vehicles, ground support equipment, aircraft, radar systems, and vacuum chambers. Some connector designs feature integrated grommets for wire sealing.

MIL-C-5015 connector gaskets are heavy-duty, circular connectors that are used in military, aerospace, industrial, rail, robotics, and heavy equipment applications. MIL-C-5015 has been superseded by MIL-DTL-5015 and derivatives such as SAE-AS50151; however, many modern connectors are designed to mate with older MIL-C-5015 connectors.

MIL-C-83723 connector gaskets meet the requirements of a U.S. military specification (now MIL-DTL-83723) for environmentally sealed circular electrical connectors that feature bayonet or threaded couplings. Applications include aircraft, ground vehicles, and telecommunications. Like the connects that house them, MIL-C-83723 connector gaskets withstand harsh conditions.

ARINC connector gaskets are used with connectors such as ARINC 600, a standard for avionics rack and panel connectors. They resist vibration and extreme temperatures, and feature environmental or hermetic sealing for protection against moisture, jet fuel, or other fluids. ARINC connector manufacturers include Amphenol, TE Connectivity, and PEI-Genesis.

LEMO connector gaskets are designed for LEMO connectors, a type of high-quality connector that’s known for its push-pull latching system. Due to their ruggedness, these connectors are used with industrial automation, aerospace, scientific research, and medical applications, including imaging, monitoring, and surgical equipment.

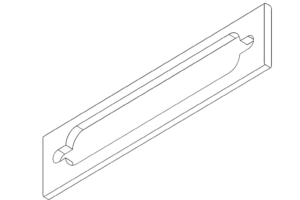

MTC connector gaskets are modular, miniature rectangular connectors that are designed for environmentally sealed applications. These electrical connectors prevent moisture, dust, and other contaminants from entering the connector system where it joins a cable or housing. Connector manufacturers include TE Connectivity and Amphenol.

EMI/RFI connector gaskets are available in multiple geometries and standards to match military, aerospace, and industrial connectors.

Watch this video to learn more about SSP’s EMI shielding silicones, which we use to fabricate EMI connector gaskets.

SSP makes the materials shown in the table below. Contact us to discuss your application. SSP can help you to select the best material for an EMI connector gasket, and we can help you compare a conductive silicone vs. fluorosilicone EMI gasket for your application.

Material | Shielding Effectiveness | Durometer | Fuel/Oil Resistance | Temp Range | Meets MIL-DTL-83528 |

Conductive Silicone (Silver‑Aluminum) | 90–120 dB | 65–75 | Moderate | –55 to +160°C | Yes |

Conductive Fluorosilicone (Silver‑Aluminum) | 90–120 dB | 70–80 | Excellent | –55 to +200°C | Yes |

80–100 dB | 65–75 | Good | –55 to +160°C | Yes | |

100–120 dB | 65–75 | Moderate | –55 to +160°C | Yes | |

110–130 dB | 65–75 | Good | –55 to +160°C | Yes |

EMI/RFI connector gaskets provide both electromagnetic shielding and environmental sealing at the interface between a connector and its mounting surface.

Galvanic corrosion can degrade shielding performance and shorten gasket life. Material selection should match the connector shell and enclosure metals. SSP makes corrosion resistant EMI gasket materials, and we fabricate these materials into connector gaskets.

Housing Material | Recommended Gasket Material | Notes |

Aluminum (Alodine/Anodized) | Best match for similar galvanic potential | |

Stainless Steel | Prevents dissimilar metal corrosion | |

Magnesium Alloys | Reduces galvanic mismatch | |

Titanium | Nickel‑Graphite or Silver‑Nickel | Stable in aerospace environments |

Composite Enclosures | Any conductive elastomer | No galvanic interaction |

Most EMI connector gaskets follow:

Note: Custom thicknesses available for non‑standard compression requirements

SSP provides full in‑house manufacturing for EMI/RFI connector gaskets:

Contact SSP for a quote.

This section contains answers to frequently asked questions (FAQs) about EMI connector gaskets.

Conductive silicone, conductive fluorosilicone, nickel‑graphite silicone, silver‑aluminum silicone, and silver‑nickel silicone are the most common materials.

Yes. Conductive elastomers provide both EMI shielding and IP‑rated environmental sealing when properly compressed.

Most conductive elastomers are designed to meet MIL‑DTL‑83528 shielding requirements.

Yes. Conductive fluorosilicone and silver‑nickel materials are widely used in aerospace, defense, and high‑reliability electronics.

Service life depends on environment, but high‑quality silicones typically provide 10–20+ years of performance.

Most conductive elastomers provide 80–120 dB of attenuation from 20 MHz to 10 GHz.

Yes. SSP manufactures custom shapes, sizes, and materials for unique connector interfaces.

Match the gasket filler metal to the enclosure metal. Silver‑aluminum pairs well with aluminum; silver‑nickel pairs well with stainless steel.

A gasket with an integrated stop feature that prevents over‑compression during assembly.