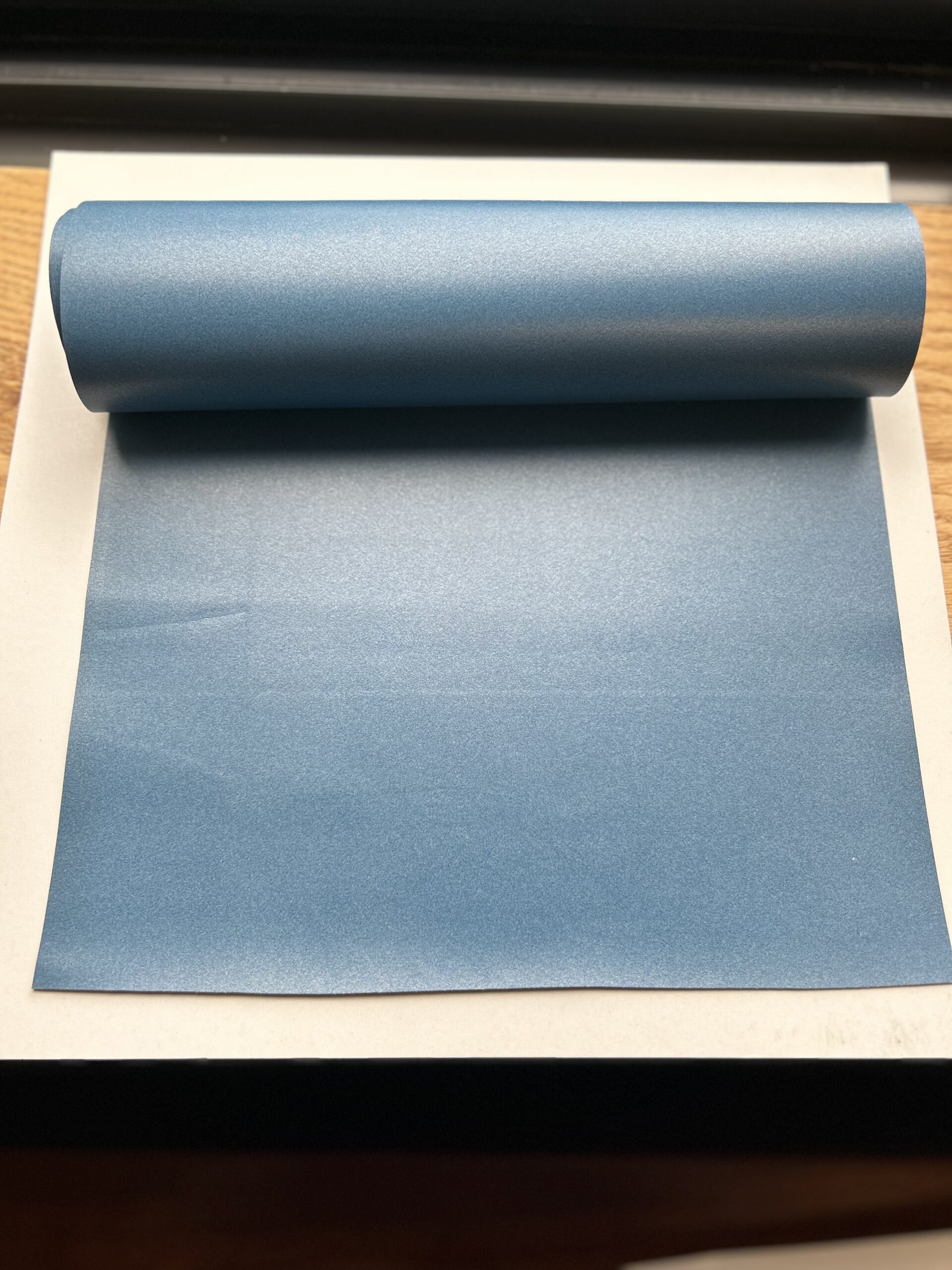

MIL-DTL-83528 Type A

CHO-SEAL 1215 alternative. SSP2569-65 is a 65-durometer, silver-copper EMI shielding silicone. MIL-DTL-83528 Type A. QPL Listed.

These EMI shielding silicones have the highest level of electrical conductivity. They contain silver-coated particles and include offsets to CHO-SEAL 1215 and CHO-SEAL 1212 from Parker Chomerics

Choose electrically conductive silicones sheets, rolls, moldable compounds, extrusions, EMI O-rings, or EMI gaskets.

SSP’s most conductive EMI shielding silicones have silver-coated particles and the highest level of electrical conductivity. They include QPL certified MIL-DTL-83528 Type A and Type K. There’s also a silver-aluminum silicone with optimum surface conductivity and a silver-nickel fluorosilicone for harsh environments.

CHO-SEAL 1215 alternative. SSP2569-65 is a 65-durometer, silver-copper EMI shielding silicone. MIL-DTL-83528 Type A. QPL Listed.

CHO-SEAL 1212 alternative. SSP2571-85 is an 85-durometer silver-copper EMI silicone that meets MIL-DTL-83528 Type K. QPL listed.

SSP2476-65 is a silver aluminum filled silicone elastomer designed for optimized surface conductivity.

SSP482-75 is a 75-durometer, electrically-conductive, silver-nickel silicone shielding elastomer that’s designed to meet MIL-DTL-83528 Type L. Find out if this shielding silicone is right for your EMI RFI gaskets.

SSP482F-75 is a 75-durometer, very conductive, silver-nickel fluorosilicone that combines EMI shielding with resistance to harsh environments.

Silicone materials are widely regarded for their versatility and robustness in industrial and engineering applications. Among these, electrically conductive silicones represent a unique class of materials that combine the inherent advantages of silicones—such as flexibility, chemical resistance, and thermal stability—with the ability to conduct electricity.

For engineers, these materials open up a broad range of opportunities for innovative designs and solutions in electronics, telecommunications, automotive, aerospace, and medical devices. Learn more about the properties, types, applications, and considerations for using electrically conductive silicones.

Electrically conductive silicones derive their functionality from their dual ability to insulate and conduct electricity. This is achieved by incorporating conductive fillers into the silicone matrix. The primary properties that make them appealing to engineers include:

Engineers have a wide array of electrically conductive silicones to choose from, depending on the application and performance requirements.

The main types include:

Electrically conductive silicones find applications across various industries, addressing challenges in electrical connectivity, thermal management, and environmental protection.

While electrically conductive silicones offer numerous benefits, their selection and application require careful consideration to ensure optimal performance.

The field of electrically conductive silicones is evolving rapidly, driven by advancements in materials science and the increasing demand for high-performance electronic and energy devices. Key trends include:

Conductive gaskets are specialized sealing materials designed to provide electrical conductivity (or thermal conductivity) while also maintaining a physical barrier for environmental protection.

Electrically conducive gaskets are used in applications where both electromagnetic interference (EMI) shielding and environmental sealing are required. These conductive seals prevent the leakage of electromagnetic waves (which can interfere with electronic components) and block external EMI from entering sensitive devices.

Conductive gaskets are often made of elastomers (like silicone or rubber) filled with conductive particles such as silver, nickel, or carbon. Some gaskets may also be made of metal mesh or fabric that is highly conductive.

Conductive gaskets are crucial in electronics where electromagnetic compatibility (EMC) standards must be met. They offer both electrical and physical protection.

Contact SSP for more information.

SSP also offers these other types of EMII/RFI shielding materials. We also fabricate EMI gaskets and EMI O-rings from the elastomers we make.