SSP makes conductive fabric EMI silicone gaskets that use combine our shielding silicones with an electrically conductive fabric for greater tear resistance.

Silicone rubber that’s filled with metal or metal-coated particles provides excellent EMI/RFI shielding and environmental sealing. The heavy loading of metal fills increases electrical conductivity, but can reduce tensile strength and Z-axis compression. If a material lacks sufficient tensile strength, cutting a small part with a thin cross-section may result in tearing during application or packaging. To address these concerns, Specialty Silicone Products (SSP) offers reinforced EMI silicones with an inner layer of electrically-conductive fabric.

Conductive Fabric and EMI Silicones

ArmouRFI fabric-reinforced shielding silicones are part of SSP’s family of EMI shielding silicones for military, medical, automotive, aerospace, satellite communications, robotics, and other electronics applications. As SpecShield elastomers, ArmourRFI products strike the right balance between electrical conductivity, EMI/RFI shielding, environmental sealing, and material cost. Yet these particle-filled silicones also offer superior strength for stronger, thinner EMI gaskets.

Nickel-Graphite Silicones

SSP offers two ArmourRFI products. SSP-502-65-020-Composite-NG-1 is reinforced with an inner layer of conductive fabric. SSP-502-65-032 is reinforced with an internal nickel-coated mesh. Both shielding silicones that are filled with nickel-graphite particles for silver-like conductivity – but without silver’s price volatility. Nickel-graphite filled shielding silicones in SSP’s 502 Series also offer low volume resistivity (VR), an indirect measure of EMI shielding effectiveness.

Volume Resistivity and Strength

With its inner layer of conductive fabric, SSP-502-65-020-Composite-NG-1 has VR values of 0.007 ohm/cm. In terms of shielding effectiveness then, this nickel-graphite composite is comparable to silver-coated, metal-filled shielding elastomers that are much more expensive. Importantly, SSP’s conductive-fabric reinforced nickel-graphite has a tensile strength of 950 psi and a tear “B” ppi of 165. This supports strong EMI gaskets – and thin ones, too.

Thinner and Softer EMI Gaskets

SSP-502-65-020-Composite-NG-1 is a 65-durometer shielding silicone that’s just 0.020 inches thick. Other thicknesses are available upon request, and SSP is ready to meet your application-specific requirements. In addition to 65-durometer materials, SSP’s conductive-fabric reinforced nickel-graphite shielding silicones are available in durometers as low as 40 (Shore A). Softer silicones are sometimes used in applications such as touchscreens to support device functionality.

Continuous Rolls for Cost-Effective Conversion

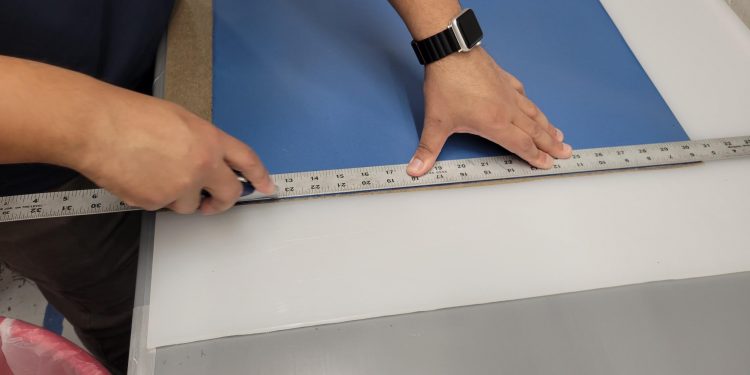

SSP supplies SSP-502-65-020-Composite-NG-1 in continuous rolls up to 15-inches wide. Compared to molded sheets, continuous rolls promote optimum yields for cost-effective material conversion. Continuous rolls also support the use of automated equipment instead of time-consuming manual operations that add labor costs. SSP supplies SSP-502-65-020-Composite-NG-1 in weeks rather than months, too. Gasket fabricators like how this EMI gasket material resists tearing and readily supports fabrication processes such as die cutting and water jet cutting.

Find Conductive Fabric EMI Silicone Gaskets

Do you need shielding silicones with conductive fabric reinforcements for added strength and optimal electrical conductivity? Would you like more information about SSP-502-65-020-Composite-NG-1, or SSP’s full line of SpecShield Elastomers? To learn more, contact SSP today.