The terms EMC gasket and EMI gasket are often used interchangeably, but they have slightly different meanings based on their scope in electromagnetic protection. Most gaskets used for EMI protection are called EMI gaskets, but when they are part of a design aimed at EMC compliance, they may be referred to as EMC gaskets.

EMI Gasket

- Primary Purpose: Prevent electromagnetic interference (EMI) from entering or exiting a device.

- Focus: Signal integrity and shielding of specific frequencies.

- Typical Use: Around electronic enclosures, connectors, and access panels.

EMC Gasket

- Primary Purpose: Help a system achieve electromagnetic compatibility (EMC)—that is, the ability to function properly in an electromagnetic environment without causing interference.

- Focus: Broader compliance goal that includes EMI shielding, ESD protection, and sometimes filtering.

- Typical Use: In systems designed to meet EMC standards such as FCC, CE, or MIL-STD.

EMI vs. EMC Gasket Comparison

- EMI gaskets are components used to block electromagnetic interference at specific points (like seams or connectors).

- EMC gaskets are part of a broader strategy to ensure a product meets electromagnetic compatibility requirements, which may include EMI shielding as well as environmental sealing and electrostatic discharge protection.

- Material and function overlap, but the terminology differs based on whether you’re referring to the component function (EMI) or the system design goal (EMC).

Feature | EMI Gasket | EMC Gasket |

Primary Function | Block EMI/RFI from entering/leaving | Ensure electromagnetic compatibility |

Scope | Narrow (focused on interference only) | Broad (includes EMI, ESD, etc.) |

Standards | MIL-STD-461, CISPR, etc. | EMC compliance (e.g., FCC, CE) |

Use Case | Shield specific joints or seams | Achieve whole-system EMC compliance |

Material Types | Conductive elastomers, metal meshes | Same materials, sometimes with added features (e.g., environmental sealing) |

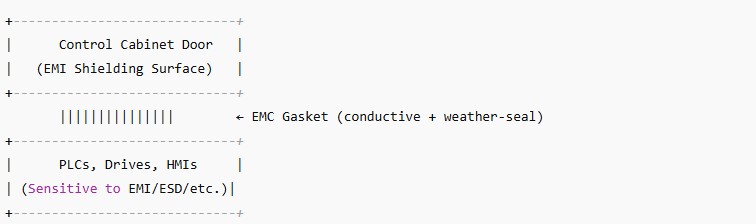

EMI Gasket Illustration 1

This image shows an EMC gasket used in a complete system with EMI, ESD, and environmental concerns. Its function is to help meet full EMC compliance (limits emissions and resists external EMI, plus sealing against dust/moisture).

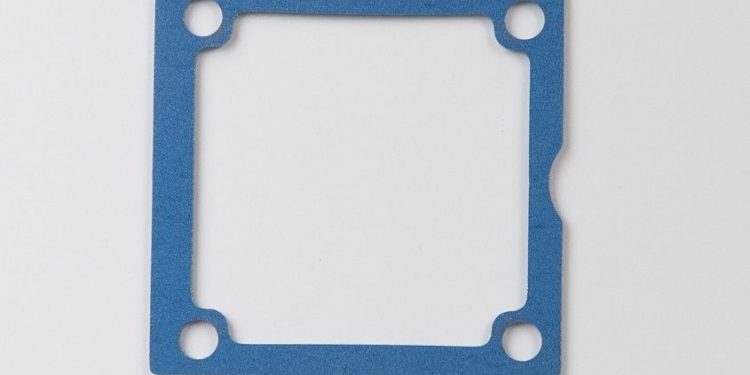

EMC Gasket Illustration 2

This image shows an EMC gasket used in a complete system with EMI, ESD, and environmental concerns. Its function is to help meet full EMC compliance (limits emissions and resists external EMI, plus sealing against dust/moisture).