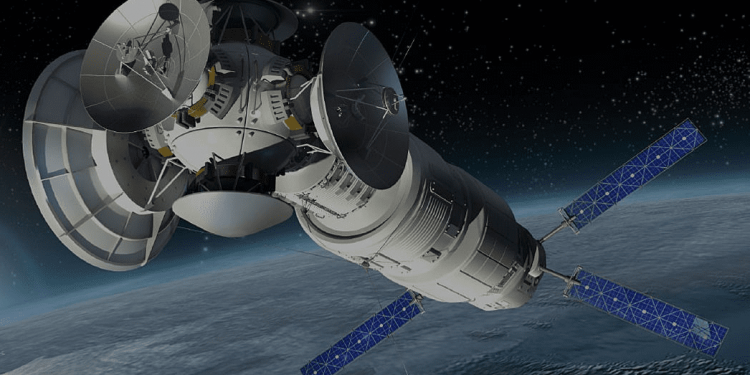

Specialty Silicone Products (SSP) makes a low outgassing silicone that passes ASTM E595 testing and remains flexible at temperatures as low as -116°C (-177°). The material, SSP2575, has a history of use in space programs and is available as a ready-to-mold compound, compression-molded sheet stock, or molded parts. Applications include satellites, rockets, and telescopes.

Low Outgassing Silicone

In the near-perfect vacuum of space, most silicone elastomers release gases. Known as outgassing, this phenomenon occurs because of the large difference in pressure between the interior of the material and outer space. With satellites and other space vehicles, outgassing can cloud camera optics or interfere with sensors and electronics.

SSP2575 meets the low outgassing requirements of ASTM E595, a test that measures volatile content released in a vacuum environment of less than 5 x 10-5 torr. ASTM E595 is the basis for NASA’s low outgassing test, which focuses on Total Mass Loss (TML) and Collected Volatile Condensable Materials (CVCM).

Independent testing from Pacific Testing Laboratories shows that SSP2575 has a TML of 0.17% and a CVCM of 0.04%. Both results meet ASTM E595 requirements. Historically, a TML of 1.00% and CVCM of 0.10% have been used as a screening level for the rejection of spacecraft materials. Testing also indicated that the amount of water vapor recovered (WVR) was 0.10%.

Space Heritage and Low Temperature Flexibility

SSP2575 has space heritage, a term that’s used to describe materials and components that have been flown in space. Importantly, this space-grade silicone remains flexible at temperatures as low -116°C (-177°F). Solar radiation can heat near-Earth region of space, but shaded objects are subjected to temperatures lower than -100°C (-148°C).

SSP2575 is black in color but can be pigmented to meet customer-specific requirements. It has a tensile strength of 1350 psi and an elongation percentage of 600%. The durometer, or hardness, of this low outgassing, low temperature silicone is 65 Shore A. To request a quote or for additional information, contact SSP.