SSP makes standard EMI waveguide gaskets in M83528 and EIA sizes from the electrically conductive silicones we make right here in the USA.

We also fabricate custom EMI waveguide gaskets for both non-military and application-specification challenges.

Compare our waveguide gasket materials to Parker Chomerics CHO-SEAL and Nolato Jabar.

Get quick lead times, low minimum order quantities, and a Certification of Analysis with every batch.

Ask SSP for a standard EMI waveguide gaskets in M83528 or EIA sizes, or for custom EMI waveguide gaskets for non-military or specialized applications. SSP offers low minimum order quantities (MOQs) and quick turn-around times.

In addition to EMI waveguide gaskets, SSP makes EMI O-Rings and other types of EMI gaskets that provide environmental sealing and electromagnetic interference protection. We also supply EMI shielding materials as sheets, rolls, extrusions, and moldable compounds.

An EMI waveguide gasket provides shielding against electromagnetic interference (EMI) with waveguide systems that transmit high-frequency electromagnetic waves. An EMI waveguide gasket combines environmental sealing with EMI shielding and is often used in military, aerospace, and satellite communications applications. SSP also makes EMI connector gaskets and other fabricated products.

EMI waveguide gaskets are electrically conductive because they are they are made of silicones and fluorosilicones that contain specialized fillers. Normally, elastomers are electrically insulating; however, compounding them with metal, bimetallic, or metal-coated particles imparts electrical conductivity.

M83528 EMI waveguide gaskets are made from shielding silicones that meet the requirements of the MIL-DTL-83528 specification, and that are fabricated into specific shapes and sizes based on this same U.S. military detail specification. Within this U.S. military detail specification, M83528/013 describes the dimensional and material requirements for EMI waveguide gaskets.

SSP also makes custom EMI gaskets for non-military and specialized applications. For example, custom gaskets for EMI waveguides are used in space applications, including ground stations.

The table below describes some available materials from SSP.

SSP Product | Base Material | Fill Material | Key Features |

Silicone | Silver-Copper | MIL-DTL-83528, Type A QPL Listed Use instead of CHO-SEAL® 1215 | |

Fluorosilicone | Silver-Copper | MIL-DTL-83528, Type C QPL Listed | |

Silicone | Silver-Copper | MIL-DTL-83528, Type K QPL Listed Use instead of CHO-SEAL® 1212 | |

Silicone | Silver-Aluminum | MIL-DTL-83528, Type B Use instead of CHO-SEAL® 1285 | |

Silicone | Silver-Aluminum | MIL-DTL-83528, Type D QPL Listed Use instead of CHO-SEAL® 1287 and 1298 |

These EMI gasket materials comply with lettered sections in MIL-DTL-83528 and are part of the M83528 Qualified Product List (QPL) from the Defense Logistics Agency (DLA). Most of the SSP materials in the table above represent offsets to CHO-SEAL® products from Parker Chomerics.

Specialty Silicone Products (SSP) makes EMI waveguide gaskets that combine environmental sealing and insulation with shielding against electromagnetic interference (EMI). This includes products for UG, CPR, and CMR flanges in MIL-SPEC and EIA waveguide sizes.

The Electronics Industries Alliance (EIA) was a trade group that defined CPR and CMR flanges along with standard sizes for rectangular waveguides. Each EIA size starts with the letters WR (waveguide rectangular) followed by the waveguide’s broad wall dimension in hundredths of an inch rounded off. Examples of EIA waveguide sizes include WR28, WR112, and WR137.

Gaskets with CPR and CMR flanges begin with the letters CPR or CMR followed by the numbers (but not the letters WR) in the EIA waveguide size. For example, CMR-137 refers to a gasket with a CMR flange and EIA waveguide size of WR137. SSP can produce gaskets like this for you from the materials we make and using our CNC knife cutter. We also mold EMI gaskets using compression molding

The table below lists common gasket flanges, including for M83528 products.

WR28 | UG-599/U | M83528/013X001M83528/013X002 |

WR42 | EG-595/UEG-597/U | M83528/013X003 |

WR62 | UG-419/U | M83528/013X005 |

WR90 | UG-1736/UUG-1737/U | M83528/013X010 |

WR112 | UG-1734/UUG-1735/U | M83528/013X016 |

WR137 | UG-1732/UUG-1733/U | M83528/013X020M83528/013X021M83528/013X022 |

WR159 | UG-1730/UUG-1731/U | M83528/013X024M83528/013X025 |

WR187 | UG-1728/UUG-1729/U | M83528/013X027M83528/013X028M83528/013X029 |

WR229 | UG-1726/UUG-1727/U | M83528/013X031M83528/013X032 |

WR284 | UG-53/UUG-584/UUG-1724/UUG-1725/U | M83528/013X033M83528/013X034M83528/013X035 |

WR340 | UG-533/UUG-554/UUG-435A/UUG-437A/U | M83528/013X040M83528/013X041 |

WR650 | UG-417A/UUG-418A/U | M83528/013X042 |

WR75 waveguide full square O-ring gaskets keep waveguide runs dry and pressurized.

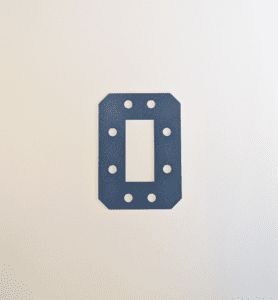

The images below are examples of EMI waveguide gaskets that SSP has fabricated from the electrically conductive shielding elastomers that we make.