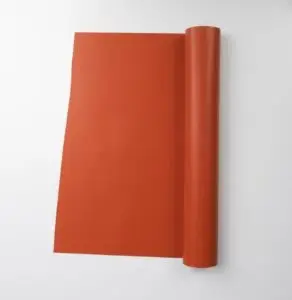

SSP2554 is an 80-durometer silicone rubber that meets the physical requirements in the AMS 3305J specification. It is used typically for parts that operate from -85°F to 400°F (-65°C to 205°C). SSP2554 remains flexible over this temperature range but is not limited to such applications. This aerospace silicone also resists weathering and petroleum-based lubricating oils. SSP2554 is supplied as a ready-to-mold compound or as compression molded sheet stock. It’s available in light gray.

The AMS 3305J specification covers silicone rubber in the form of sheets, strips, tubing, extrusions, and molded shapes. SAE International, a professional association and standards-developing organization, defines Aerospace Material Specifications (AMS) like AMS 3305J.

The shelf life for catalyzed SSP2554 is two months. Store below 80°F. Cold storage will extend the shelf left of this military and aerospace silicone.

The table below compares typical values for SSP2554 against the AMS 3305J spec. The test data was generated with (240-DCLBP) peroxide catalyst system.

Test | Specifications | Typical Values |

Shore A | 75 – 85 | 77 |

Tensile Strength, psi | 650 min | 1208 |

Elongation % | 100 min | 250 |

Tear-B, ppi | 25 min | 88 |

Comp Set (70/150°C), % | 30 min | 21 |

Specific Gravity | 1.37-1.43 | 1.40 |

Fluid Immersion (IRM901 Oil) | ||

Shore A change, points | -15 max | 5 |

Tensile change, % | -20 max | -5 |

Elongation change, % | -15 max | -7 |

Volume Change, % | 15 max | 3.8 |

Heat Age 70 hours @ 225°C | ||

Shore A change, points | 10 max | 6 |

Tensile change, % | -25 max | -22 |

Elongation change, % | -40 max | -38 |

|

| |

Low Temperature Brittle Point @ -65°C | Pass 5 of 5 | Pass |

Download the SSP2554 data sheet and compare this PDF against the AMS 3305J specs from SAE International.

Contact SSP to request a quote, or for additional information about this silicone rubber.