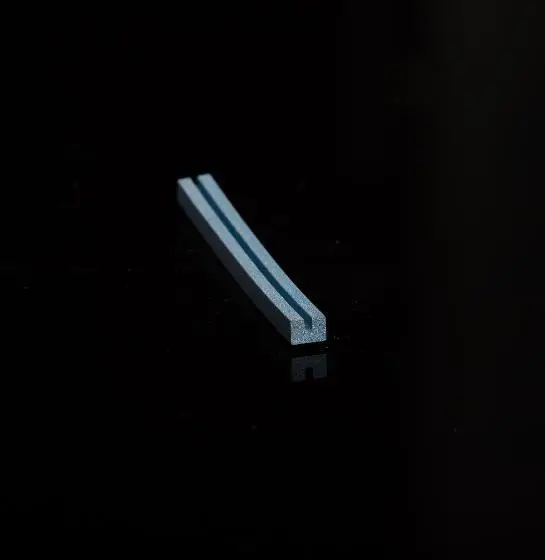

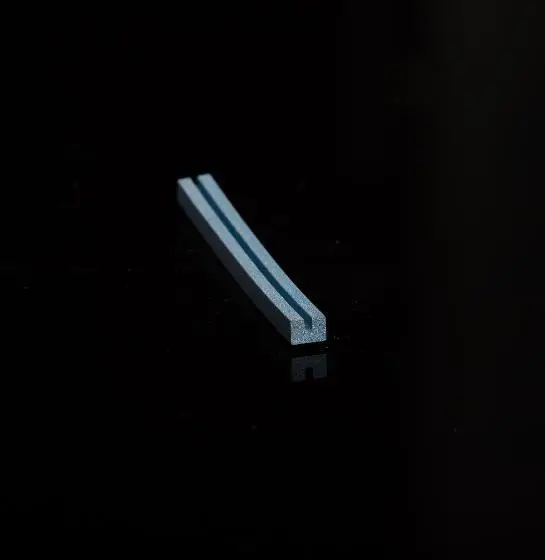

MIL-DTL-83528 Type A Extrusion

E256965 is a 65-durometer extruded EMI silicone that is filled with silver-copper particles. It is QPL listed

Specialty Silicone Products (SSP) manufactures and distributes EMI extrusions (EMI gasket extrusions) in a variety of materials, shapes, and sizes.

SSP makes EMI extrusions (EMI gasket extrusions) in the following materials. Many are MIL-DTL-83528 (MIL-G-83528) certified and are part of the M83528 QPL. Use them EMI Gaskets and EMI O-Rings.

E256965 is a 65-durometer extruded EMI silicone that is filled with silver-copper particles. It is QPL listed

E23685 is a 65-durometer extruded EMI silicone that’s filled with silver-aluminum particles. It’s tan in color and QPL listed.

E23685 is a 65-durometer extruded EMI silicone that’s filled with silver-aluminum particles. It’s dark blue in color and QPL listed.

E248670 is a 70-durometer extruded EMI fluorosilicone that’s filled with silver-aluminum particles. It is tan in color and QPL listed.

E248670 is a 70-durometer extruded EMI fluorosilicone that’s filled with silver-aluminum particles. It is dark blue in color and QPL listed

E257185 is a 85-durometer extruded EMI silicone that is filled with silver-copper particles. It is QPL listed.

E2551 is a 72-durometer extruded EMI fluorosilicone that’s filled with nickel-aluminum particles.

E2529 is a 68-durometer extruded EMI silicone that’s filled with nickel-aluminum particles.

E502F60 is a 60-durometer extruded EMI fluorosilicone that’s filled with nickel-graphite particles.

E50265 is a 65-durometer extruded EMI silicone that’s filled with nickel-graphite particles.

SSP makes EMI extrusions in the following standard shapes. Custom shapes available upon request.

SSP’s EMI extrusions are numbered according to specific codes.

Specialty Silicone Products (SSP) supplies extruded EMI elastomers in standard and custom profiles. Our manufacturing equipment includes a 40-ton Loomis extruder for EMI elastomers used in automotive, aerospace, military, medical, satellite communications, and robotics applications.

SSP’s EMI/RFI shielding elastomers include many high-quality, cost-effective offsets to materials from well-known competitors. Many of these elastomers are designed to meet the lettered requirements of MIL-DTL-83528, a U.S. military specification (MIL-SPEC) for conductive elastomeric shielding gaskets.

SSP’s EMI RFI elastomers also include compounds that are suitable for commercial application, such as aviation, where EMI shielding gaskets that provide fuel resistance may be required.

Extruded EMI elastomers from SSP provide the same properties and features as the company’s EMI elastomers in three other form factors: ready-to-mold compounds; fully-cured, conductive stock sheets, and (for some formulations) continuous rolls.

For gasket fabricators and material converters, the availability of extruded profiles from SSP means potential opportunities. Now, fabricators and converters can buy extruded EMI elastomers directly from a trusted source (SSP), eliminating the middle-man or more expensive suppliers.

Extruded EMI elastomers also provide robust design options for sealing and shielding applications. Gasket fabricators that offer value-added service such as joining or splicing can benefit, too.

Extrusion is a material-formation process that forces a feedstock through a die or series of dies, and produces a specific shape with a constant cross-section. Examples of these cross-sectional shapes include circles, half-circles, squares, rectangles, D-shapes, and P-shapes.

In the case of SSP’s EMI RFI elastomers, the feedstock consists of a silicone or flurosilicone base for environmental sealing, and metal or metal-coated particles for electrical conductivity and EMI shielding.

Depending on the tooling that’s used, SSP’s EMI elastomer extrusions can have very thick or very thin cross-sections. These extrusions can also be solid or hollow. Solid rubber extruded profiles are made by continuous extrusion. Hollow rubber profiles can handle greater compressive forces.

SSP’s EMI elastomers have the same properties and features whether a material is supplied as an extrusion, sheet, roll, or ready-to-mold compound.

For example, SSP238-65 is a 65-durometer, electrically-conductive silver-aluminum shielding silicone that’s designed to meet the requirements of MIL-G-83528, Type B. Regardless of form factor (i.e., extrusion, sheet, roll, or compound), this material has the same tensile strength, thermal stability range, volume resistivity, and shielding effectiveness.

All EMI elastomers are not available in all four form factors, however. For technical buyers, it’s important to note that SSP’s extrusions do not include softer silicones and reinforced materials, even higher-durometer compounds that contain fabric reinforcements. This means that SSP’s 30, 40, and 45-durometer materials are available only as moldable compounds, sheets, or rolls.

Fabric-reinforced EMI silicones are 65-durometer materials, but they’re not available as extrusions.

For gasket fabricators, material converters, and manufacturers, it’s important to understand that SSP extrudes EMI elastomers in long lengths that are coiled, boxed, and shipped. Companies that use die cutting, water jet cutting, laser cutting, or other material conversion methods can then cut these long, standard lengths to shorter, stock lengths; or to custom sizes for specific applications.

Gasket fabricators who provide additional services such as design assistance, splicing, and gasket taping can also leverage their capabilities by providing a value-added solution.

SSP can help you to identify the EMI shielding materials that you or your customers require. As a full-line supplier of standard and custom silicones, we have the technical knowledge and application expertise to be more than just your material supplier. As your strategic sourcing partner, SSP can recommend the right commercial, medical, and military silicones for your specific project.

Contact us for more information.

Note: For photos of some of our extruded EMI elastomers, visit this album in Google Photos

EMI extrusions are electrically conductive silicone or fluorosilicone profiles manufactured in continuous lengths. They provide EMI/RFI shielding and environmental sealing for enclosures, housings, and electronic systems.

SSP produces EMI extrusions using conductive silicones and fluorosilicones filled with metal or metal‑coated particles, including nickel‑graphite, silver‑aluminum, silver‑nickel, and silver‑copper.

Common profiles include solid and hollow O‑rings, D‑shapes, P‑shapes, rectangles, squares, and custom cross‑sections. SSP can also produce extrusions to customer‑specified dimensions.

Yes. SSP manufactures multiple materials that meet MIL‑DTL‑83528 specifications, including QPL‑listed silver‑aluminum and silver‑copper conductive elastomers.

Absolutely. SSP can cut extrusions to length, splice them into O‑rings, or bond them into custom gasket shapes using conductive or non‑conductive adhesives.

Typical applications include military electronics, aerospace systems, communication equipment, ruggedized enclosures, and any design requiring both EMI shielding and environmental sealing.

Yes. SSP offers fluorosilicone EMI extrusions that provide excellent resistance to fuels, oils, solvents, and harsh chemicals.

Yes. SSP can design and manufacture custom tooling for unique cross‑sections, specialty geometries, or application‑specific sealing requirements.

Extrusions are ideal for long lengths, continuous seals, and applications requiring flexible installation. They also reduce tooling costs compared to molded parts.

Yes. SSP supports prototyping, short runs, and full‑scale production depending on project requirements.