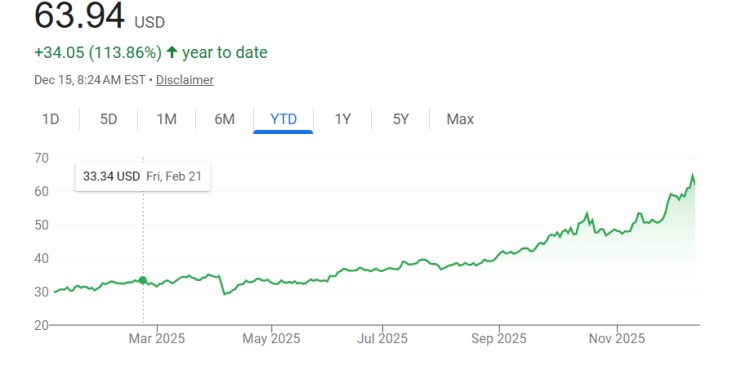

How high will silver prices rise? As of December 15th, the price of silver has risen by over 113% this year. If you’re buying EMI gaskets or shielding silicones that contain silver-coated fillers, you’ve noticed that you’re paying more. It’s not 113% more, but some EMI gasket materials have nearly doubled in price. What’s going on, and what can you expect in the future?

Silver Prices and Defense Spending

Silver-filled silicones are the most common EMI gasket material for military applications. U.S. defense spending is rising, and the budget for Fiscal Year 2026 contains significant increases. MIL-DTL-83528, a specification for elastomeric EMI shielding gaskets, calls out silver-filled materials, including EMI shielding silicones with silver-coated aluminum or silver-coated copper fills.

The suppliers of these fillers buy silver in bulk, block form and then process it before coating it over aluminum or copper. By the time that silver-coated fillers are sold to compounders like SSP, additional value has been added. In addition to the high price of silver then, compounders must absorb additional material costs, as well as the costs of labor and processing.

Silver-Filled Silicones and EMI Gasket Costs

As the graph that accompanies this article shows, silver prices aren’t just climbing. They’re rising quickly and frequently. SSP is doing our best to control the costs of EMI gaskets and silver-filled elastomers; however, we can’t absorb this type of increase. Our nickel-graphite materials provide a cost-effective alternative, but MIL-DTL-83528 requires silver or silver-coated fills.

Because of rising silver prices, SSP is now quoting products with silver-coated fills on an order by order basis. This includes SSP2569-65 and SSP2571-85, silver-copper silicones that meet MIL-DTL-83528 Type A and Type K requirements, respectively. It also includes SSP2368-65, a MIL-DTL-83528 Type B silver-aluminum silicone, and other elastomers with silver-coated fillers.

Managing EMI Gasket Costs

SSP continues to monitor rising silver prices and will do our best to minimize their effects on EMI gaskets. We can’t control the price of silver, of course, but we can sometimes recommend cost-saving strategies. Examples include molded EMI frame gaskets that reduce material waste, and bonded EMI O-rings that both reduce costs and improve performance.

Contact SSP to discuss your EMI shielding application.